The Importance of Incinerator Maintenance

At Macrotec we have witnessed the crucial role that incinerators play in waste management. Incinerators are responsible for safely disposing of hazardous and non-hazardous waste, reducing the environmental impact of landfill sites, preventing the spread of diseases, and reducing the environmental impact of hazardous waste.

However, the proper functioning of incinerators depends on regular servicing and maintenance. Poorly maintained incinerators can pose serious risks to employees, the environment, and business operations. In this article, we will explore the key aspects of incinerator servicing and the critical role it plays in waste management.

Risks of Poorly Maintained Incinerators

Poorly maintained incinerators can result in a range of risks, including:

- Increased emissions of harmful gases and particulate matter, which can cause respiratory problems and other health issues for employees and nearby communities.

- Fire hazards due to a build-up of combustible materials, such as dust and debris.

- Malfunctions and breakdowns that can result in expensive repairs, downtime, and lost productivity.

- Malfunctioning of incinerators

- Non-compliance with environmental regulations and standards, which can lead to fines, legal action, and damage to your business reputation.

Benefits of Regular Incinerator Servicing and Maintenance

- Regular incinerator servicing and maintenance can help to mitigate these risks and provide a range of benefits, including:

- Improved safety for employees and the environment by reducing the risk of hazardous emissions and fires.

- Increased reliability and performance of the incinerator, reducing the risk of breakdowns and downtime.

- Improved compliance with environmental regulations and standards, avoiding fines and legal action.

- Longer lifespan of the incinerator, reducing the need for expensive repairs and replacements.

- Enhanced efficiency and cost-effectiveness by identifying and addressing potential issues before they become major problems.

Critical Aspects of Incinerator Servicing

Several critical aspects of incinerator servicing require regular inspection and maintenance to ensure safe and efficient operation. When planning maintenance, it is important to take into concideration the availability and lead times of Incinerator Spare Parts.

- Burners:

Efficient and reliable burners are crucial for proper waste incineration. Regular inspection and maintenance of burners can help ensure proper operation, improve combustion, reduce emissions, and improve the lifespan of the incinerator. - Combustion Fans:

Combustion fans are responsible for supplying the necessary oxygen to the burner for proper combustion. Regular maintenance of combustion fans can help ensure proper airflow and reduce the risk of downtime due to fan failure. - Refractory:

Refractory materials are used to line the walls of the incinerator to protect against high temperatures and corrosive gases. Regular inspection and maintenance of the refractory can help ensure its integrity, reduce the risk of damage or failure, and prevent heat loss. - Heat Exchanger:

The heat exchanger is responsible for transferring heat from the waste gases to the water or air. Regular inspection and maintenance of the heat exchanger can help ensure its efficiency and prevent leaks or damage. - Filtration:

The filtration system is responsible for removing harmful pollutants and particles from the waste gases before they are released into the environment. Regular maintenance of the filtration system can help ensure its effectiveness, reduce emissions, and improve air quality. - Oxygen Analyser and CEMS:

The oxygen analyser is responsible for combustion control, ensuring the correct amount of combustion air goes into the incinerator, while the Continuous Emission Monitoring System (CEMS), is responsible for measuring and recording the total emissions for regulatory purposes.

The Cost-Effectiveness of Regular Incinerator Servicing

While regular incinerator servicing requires an investment of time and money, it is more cost-effective than emergency repairs and replacements. By identifying and addressing potential issues before they become major problems, you can avoid costly downtime, repairs, and replacements. In addition, regular servicing can improve the efficiency and performance of the incinerator, reducing operating costs and increasing the lifespan of the machine.

In conclusion, incinerator servicing and maintenance are critical aspects of waste management that should not be overlooked. Regular inspection and maintenance of critical components, such as combustion burners, fans, refractory, heat exchangers and filtration are crucial.

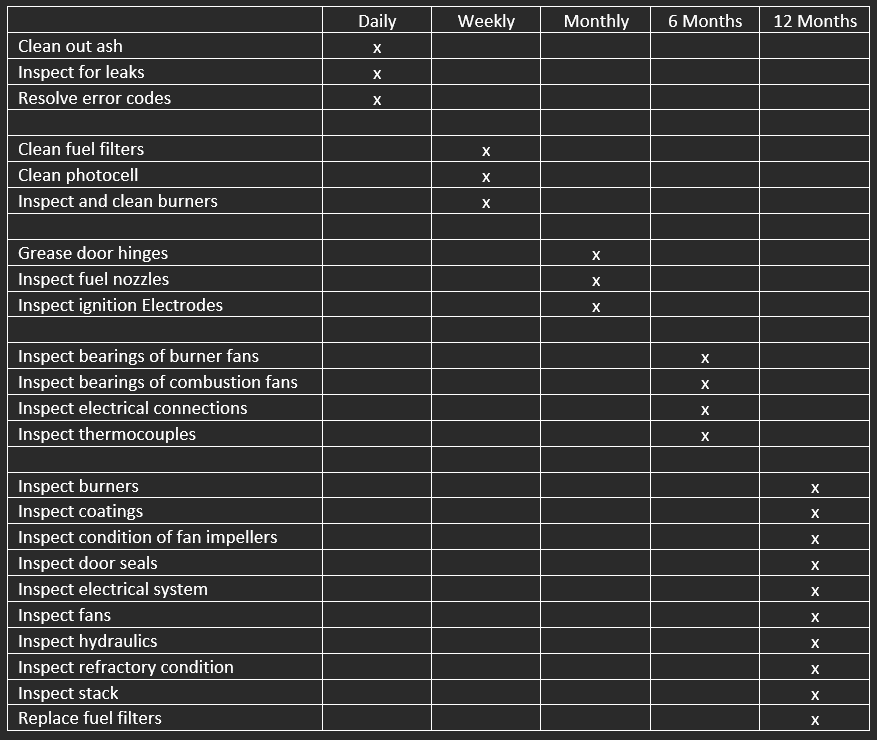

Incinerator Maintenance Checklist

This is a typical incinerator maintenance checklist.