Biomass Fired

Our Biomass Incinerators utilises biomass fuels as available to bring the incinerator up to temperature and as an auxiliary fuel. This replaces diesel or gas for sites that are remote or don’t have a readily available supply of fuel.

Easy Installation

With no diesel or gas supply infrastructure needed, installation is a lot easier and faster, making it ideal for quick deployments during emergencies or for remote mines or military camps.

Certification

Macrotec is certified to the following standards:

ISO 9001:2015 | Quality Management Systems

ISO 14001:2015 | Environmental Management Systems

ISO 45001:2018 | Occupational Health & Safety Management

Design

Our Biomass Incinerators are very similar to our standard incinerators, with two chambers, combustion air fans, and a stack.

Incinerator

All our incinerator models have two chambers, with a large hearth to help distribute the waste, and a large secondary chamber to promote settling of particulate matter (dust). The chambers are also sized for a two second reaction (retention) time.

We use a high temperature alumina-silicate refractory, with a cold crushing strength of 80Mpa and service temperature of 1,500˚C to cast our incinerators. The refractory is acid resistant with very high abrasion resistance. We also insert 100mm of low-density insulation, giving an incubator a typical R-value of 1.54m²K/W, minimising heat loss for lower fuel consumption and a safer working environment.

All our incinerators operate on a continuous feed basis. This entails waste being loaded on fixed intervals with ash being removed from the rear without the need to stop. Due to not stop and starting as you would with a batch incinerator, biomass fuel consumption is improved (no preheat required), and emissions are also improved due to a more controlled combustion process.

Combustion Air

Our incinerator combustion air is designed to optimize turbulence and mixing in the primary chamber, by blowing in the combustion air at high velocity over the waste. This promotes combustion and increases combustion efficiency by ensuring that combustion gasses are adequately mixed with oxygen for the oxidation of combustible gasses.

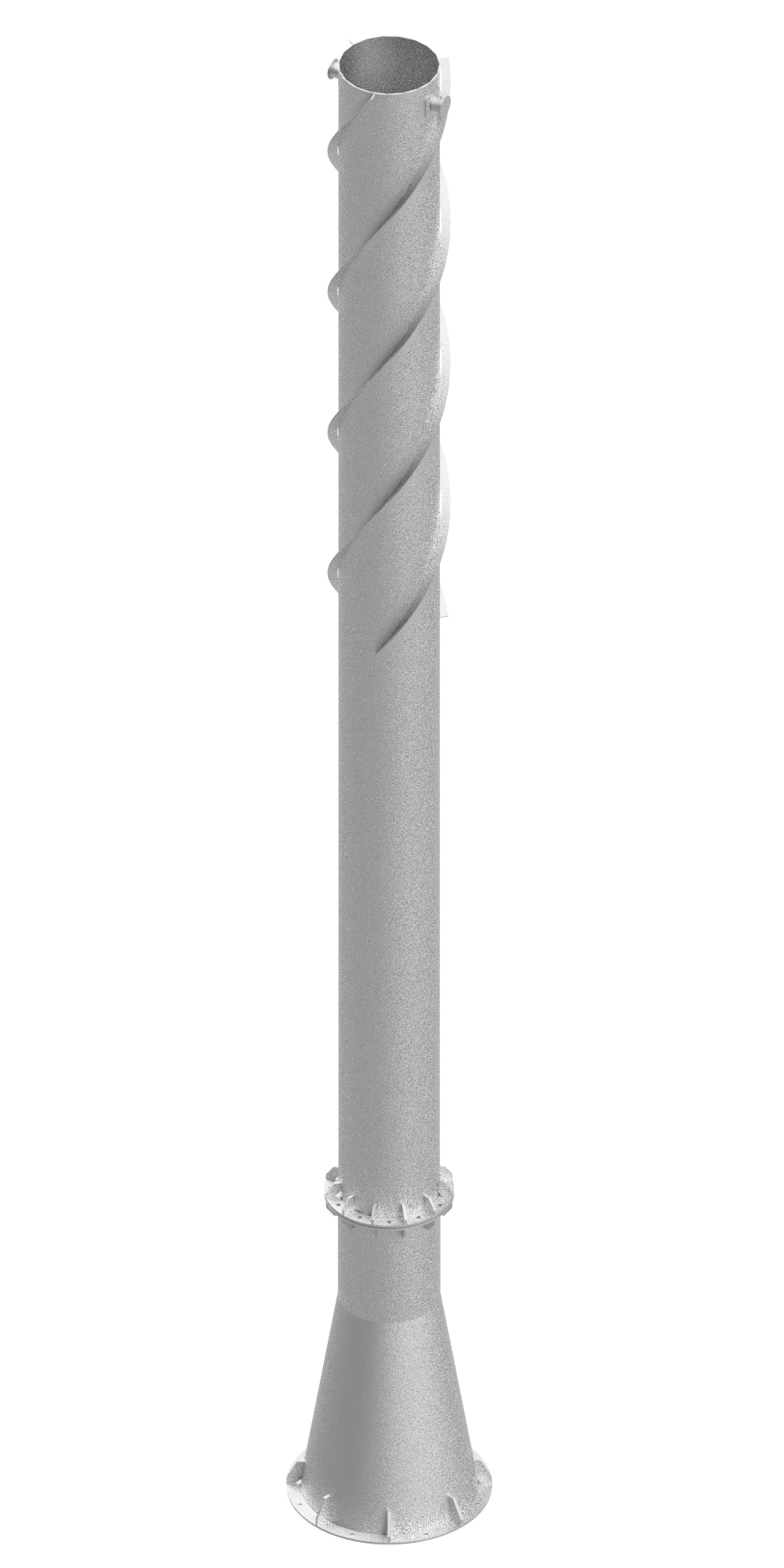

Stack

The standard stack height on our incinerators ranges from 7m to 15m, depending on the model size, with taller stacks optional. Our stacks are taller than most of our competitors for good reason, the increased height increases the draft, increasing the velocity of the flue gas, releasing it at greater height, resulting in better dispersion.

According to EPA (Environmental Protection Agency – USA), Good Engineering Practice for stacks is calculated as H + 1.5L, where H is the height of the building itself or any significant nearby structure or structures and L is the lesser of the projected height or width of the building in question. If this is applied to the typical building in a remote setting, away from larger building, a minimum stack height of 7m would be recommended. This needs to be calculated on a site-by-site basis and might require a taller stack.