Ceramic Filter Elements

-

- Incineration

- Cremation

- Gasification & Pyrolysis

- Biomass Combustion

- Nuclear Waste Processing

- Mineral Processing and Smelting

- Coal Drying

- Cement Production

- Foundry Processes

- Waste-to-Energy

- Oil and Gas

-

- General Enquires

- Technical Support

- Hot Gas Filtration Brochure

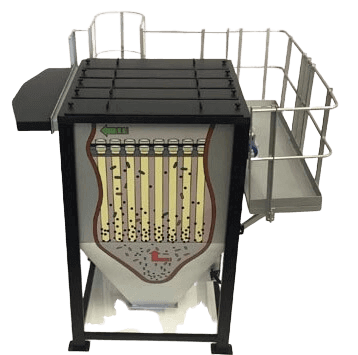

Ceramic Filter Elements

For optimum performance and reliability, all our filter elements are formed from engineered fibres using a fully automated process. During manufacture, forming times and pressures are strictly maintained to achieve stable pressure drop and bulk density. Every tenth element manufactured is tested and recorded, then packed in bar coded packaging to ensure complete traceability.

For the best possible performance, each element is fully machined to strict tolerances. A specially formed surface allows dust to form a conditioned layer that assists the removal of submicron particles. Gas flow is improved, and more evenly distributed, by the unique tapered profile of each element. The taper makes it easier to clean the filter element.

Our Filter Elements can be purchased as replacements for a current filtration system, or as part of our Hot Gas Filtration systems.

Advantages of Ceramic Filtration

- Ceramic elements can withstand temperatures of up to 1,000°C, compared to 140°C to 180°C for bag filters.

- Ceramic elements are non-flammable.

- Ceramic elements are resistant to acids and alkalis.

- Operating temperature of up to 450°C, allowing for scrubbing at the most efficient temperatures and almost all processes.

- No need for reaction towers or cyclones.

- Lowest emission level achieved, with constant and reliable performance.

Types of filter elements

There are three standard types of element:

- G3 is a ceramic element which will operate at temperatures up to 1100°C.

- G4 is a mineral element which will operate at temperatures up to 750°C.

- S4 is mineral-based, manufactured from Low Bio-Persistent Fibres element suitable for temperatures up to 1100°C.

- Elements available in 1000mm and 1250mm lengths.

All our filter elements are produced with an outside diameter of 60 mm (tapered to 55 mm) and are 500 mm, 1000 mm or 1250 mm long. These dimensions have been shown to achieve optimum performance for particulate removal and dry scrubbing.

Advantages of filter elements

All our filter elements are manufactured from known engineered fibres, using a fully computerised process. Forming times and pressures are tightly controlled to achieve stable bulk density and a specific pressure drop.

Unlike conventional bag filters and other types of filters, ceramic filters are highly efficient – up to 99.99%. They are able to remove sub-micron sized particles including nano particles.

- A ceramic filtration system which is capable of outperforming it’s competitors.

- Meeting the latest directives including I.E.D. and is considered to be Best Available Techniques (BAT).

- Filters are self-cleaning, allowing continuous filtration to temperatures up to 650°C. Removing sub-micron particles and achieving particulate emission levels of below 1 mg/m3.

Benefits of filters in dry scrubbing applications

The most important benefit is that there are no filter bags to catch fire.

Removing HCl at temperatures above 400°C prevents reformation of dioxins. A certain amount of the sodium bicarbonate converts to a gas, which means that there is less material to go to land-fill. This makes sodium bicarbonate preferable to lime where environmentally friendly disposal is important.

Using high-temperature ceramic filters and dry scrubbing with sodium bicarbonate and/or activated carbon achieves outstanding emission results.