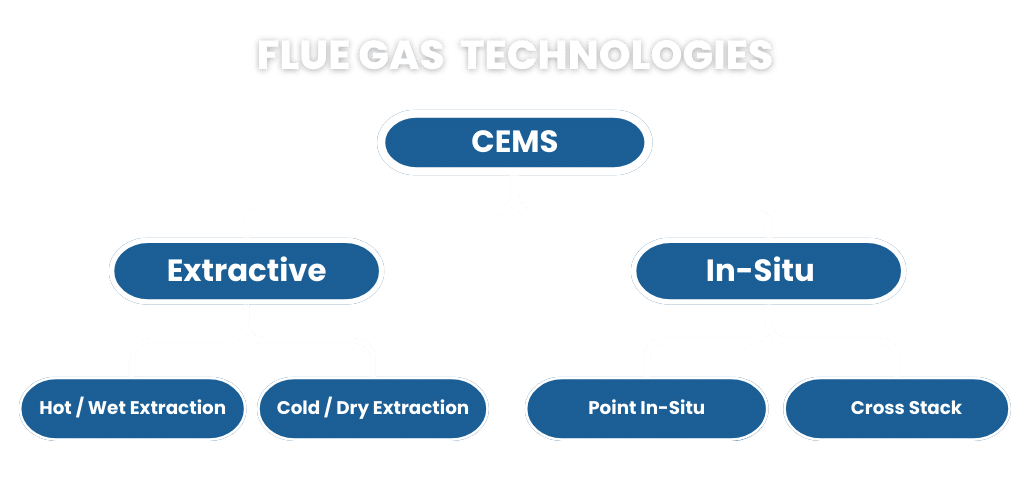

Continuous Emission Monitoring Systems (CEMS)

Macrotec provides an array of Continuous Emission Monitoring Systems (CEMS), along with cutting-edge Flow Measurement Instruments, and Combustion Analysers. Our comprehensive services include the engineering and design of process monitoring systems, equipment selection, installation, training, commissioning, maintenance, and remote monitoring. These systems are crucial for industries committed to adhering to environmental regulations and optimizing their operational efficiency.

Flue Gas Analysers

Macrotec and SICK provides an extensive selection of gas analysers, utilizing a diverse array of robust measurement principles. Offering both in-situ and extractive measurement technologies, we are equipped to furnish complete facilities with solutions that cater to a wide range of systems and complex measurement challenges.

To effectively reduce emissions, enhance production quality and efficiency, it’s crucial to accurately analyse and monitor gas concentrations. SICK employs cutting-edge technologies and established measurement principles to deliver forward-thinking solutions. These solutions are adept at measuring aggressive or toxic gases and are suitable for installation in explosion-prone areas. Additionally, digital services like the Monitoring Box provide not just condition monitoring but also the capability to analytically assess condition and application data, offering a comprehensive approach to gas analysis and monitoring.

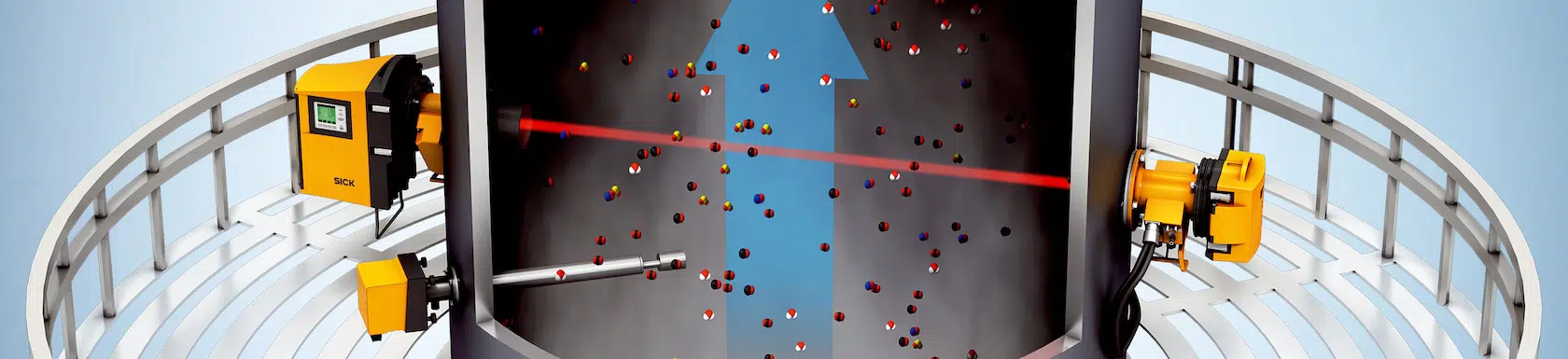

In-situ Gas Analysis

Measuring devices can be mounted at the measurement location directly in the duct or stack through which the gas flows. This device features minimal maintenance requirements and very short response times.

In-situ Analysis

For representative measurement results across the entire duct cross-section.

Optimized for single-sided installation allowing simple integration into an extremely varied range of system conditions. For example, wet gases or very high-test gas concentrations or dust loads.

Advantages

- Continuous and direct measurement, no sampling.

- Direct and unfalsified measurement.

- Fast measurement.

- Low maintenance.

- Cross-duct version for representative measurement results or measuring probe version for simple installation.

Extractive Gas Analysis

Extractive gas analysers can be used in a broad range of applications. A partial gas flow is extracted from the gas duct through selected probes, prepared and then fed to the analyser module under constant conditions. The entire gas treatment from the extraction and processing to the analysis is optimally designed for the measuring task.

Two variants of measurement technology are available:

All components that come into contact with the test gas are heated and kept above the dew point. The analysis is done under constantly hot measurement conditions and yields accurate results, even with very narrow measuring ranges. Ideal for detection of multiple gas components as well as water-soluble components such as HCl, HF or NH3.

The gas sampling can be designed with a heated or unheated test gas line. Gas drying is achieved with a high-performance gas cooler. The “cold” measurement is handled by the analyser.

Advantages

- Configurable analyser modules for a wide range of applications.

- Customized solutions designed for numerous possible measuring components.

- Accurate and reliable measurement results. Detection of aggressive, corrosive or combustible gases.

Related Articles

Flue Gas Analyser Comparison – In-Situ vs Hot/Wet vs Cold/Dry

Flue Gas Analyser Comparison In-Situ vs Hot / Wet vs Cold / Dry Flue gas analysis plays a pivotal role in optimizing combustion processes, reducing emissions, and adhering to environmental […]

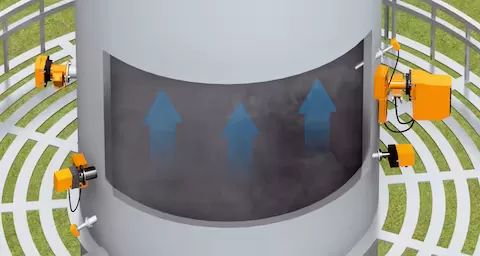

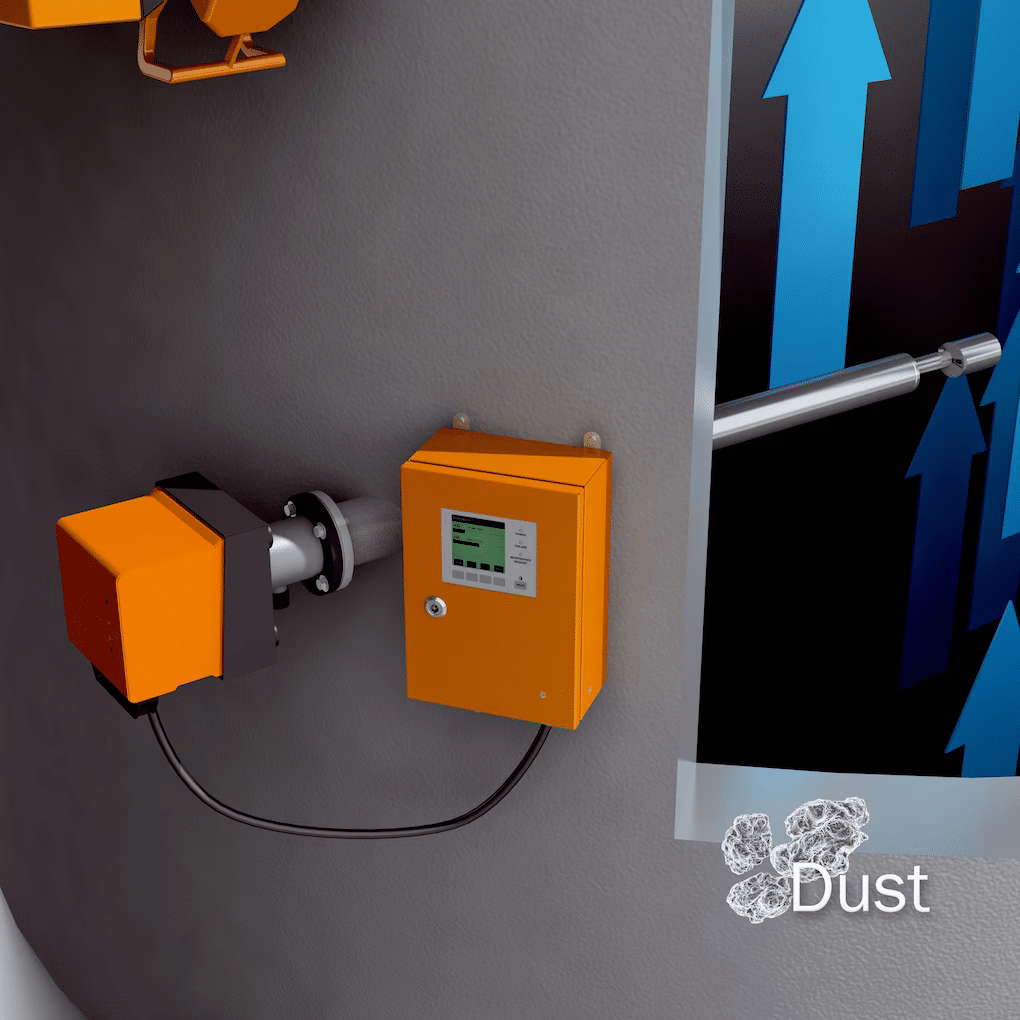

Dust Monitoring Devices

SICK is redefining the benchmark in dust measurement with its durable and low-maintenance devices, designed for detecting and monitoring dust concentrations. These dust measuring devices are seamlessly integrable into existing applications, ensuring ease of installation and commissioning. Additionally, they are user-friendly, simplifying the operation process and enhancing overall efficiency in dust measurement.

Depending on the boundary conditions, scattered light or transmittance measurement can be used for detecting dust concentrations:

Scattered light measurement principle

Light is irradiated into the measurement duct and the radiation reflected by particles is measured. It is suitable for larger gas ducts and delivers representative measurement results, even with inhomogeneous dust distributions.

The dust measuring device measures the light scattering from the particles in the direction of diffusion of the measuring light beam. The measurement takes place in the gap of a measuring probe in the gas duct. Due to the smaller measuring volume, this measurement principle is also suitable for gas duct diameters below 0.5 m.

SICK DustHunter T50

Transmittance measurement principle

Transmittance measurement technology detects light attenuation by dust particles. Transmittance dust measuring devices are well suited for medium to high dust concentrations and large gas duct diameters.

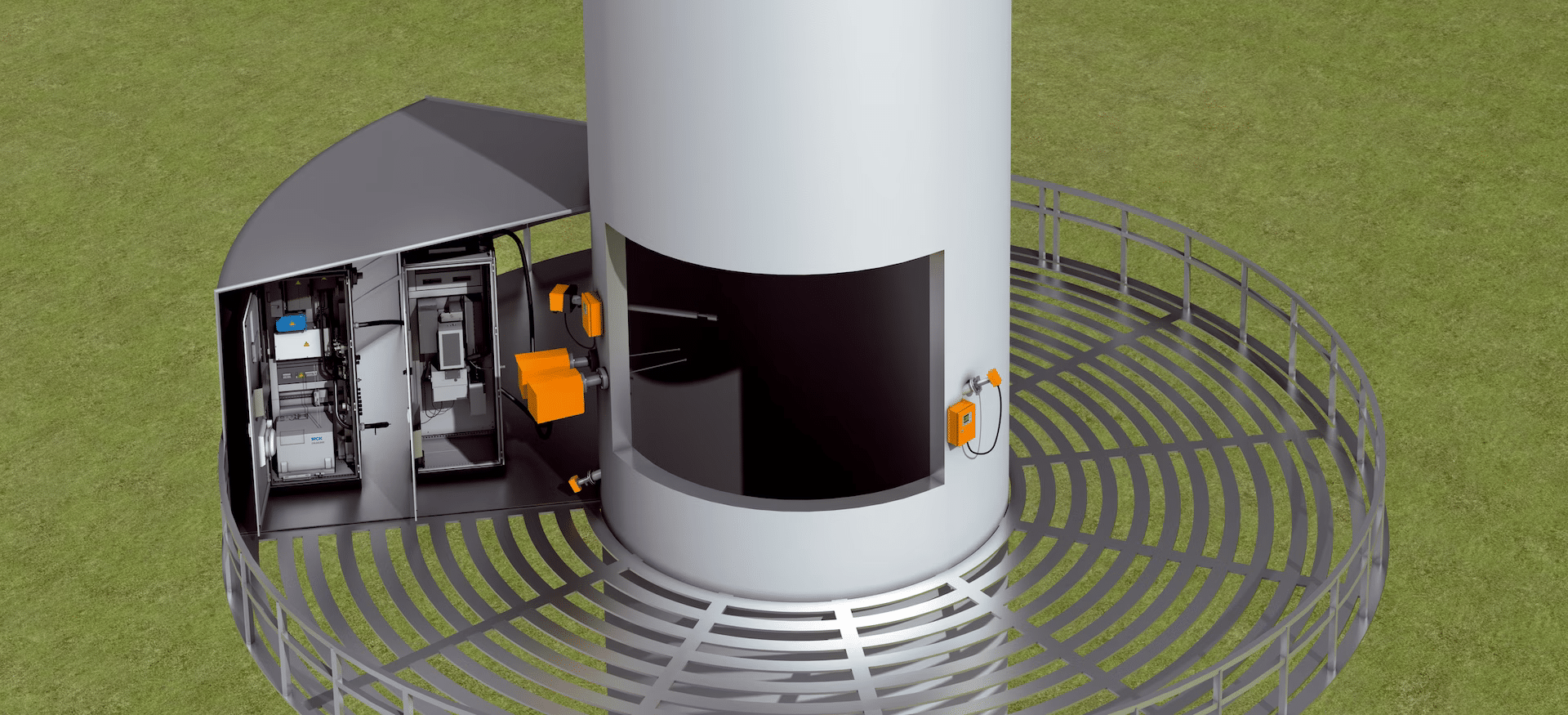

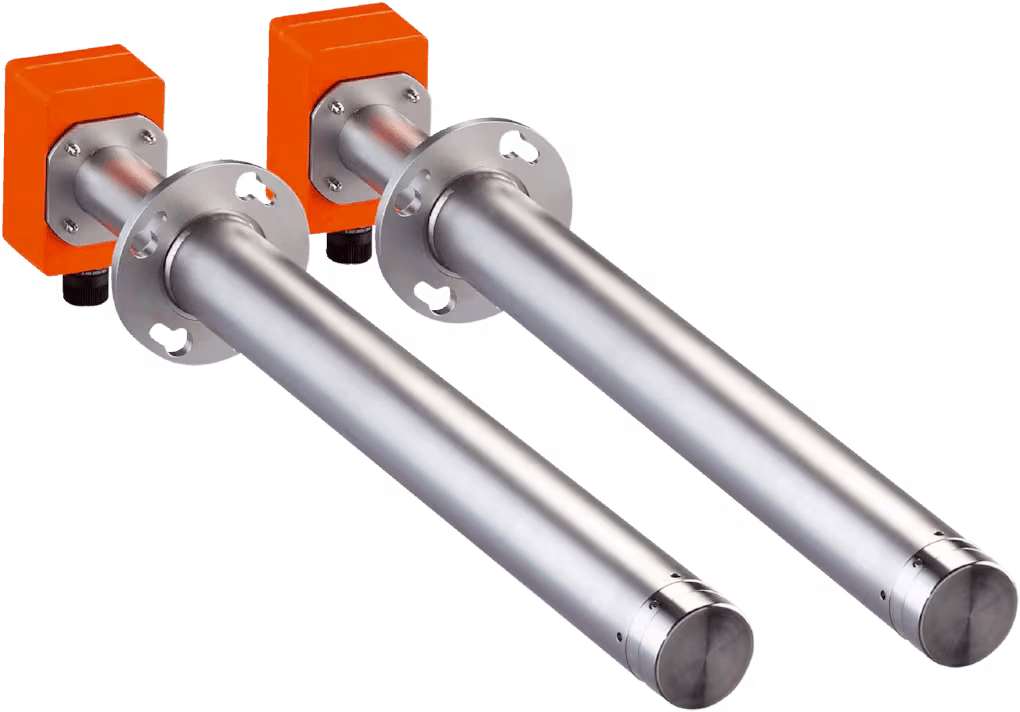

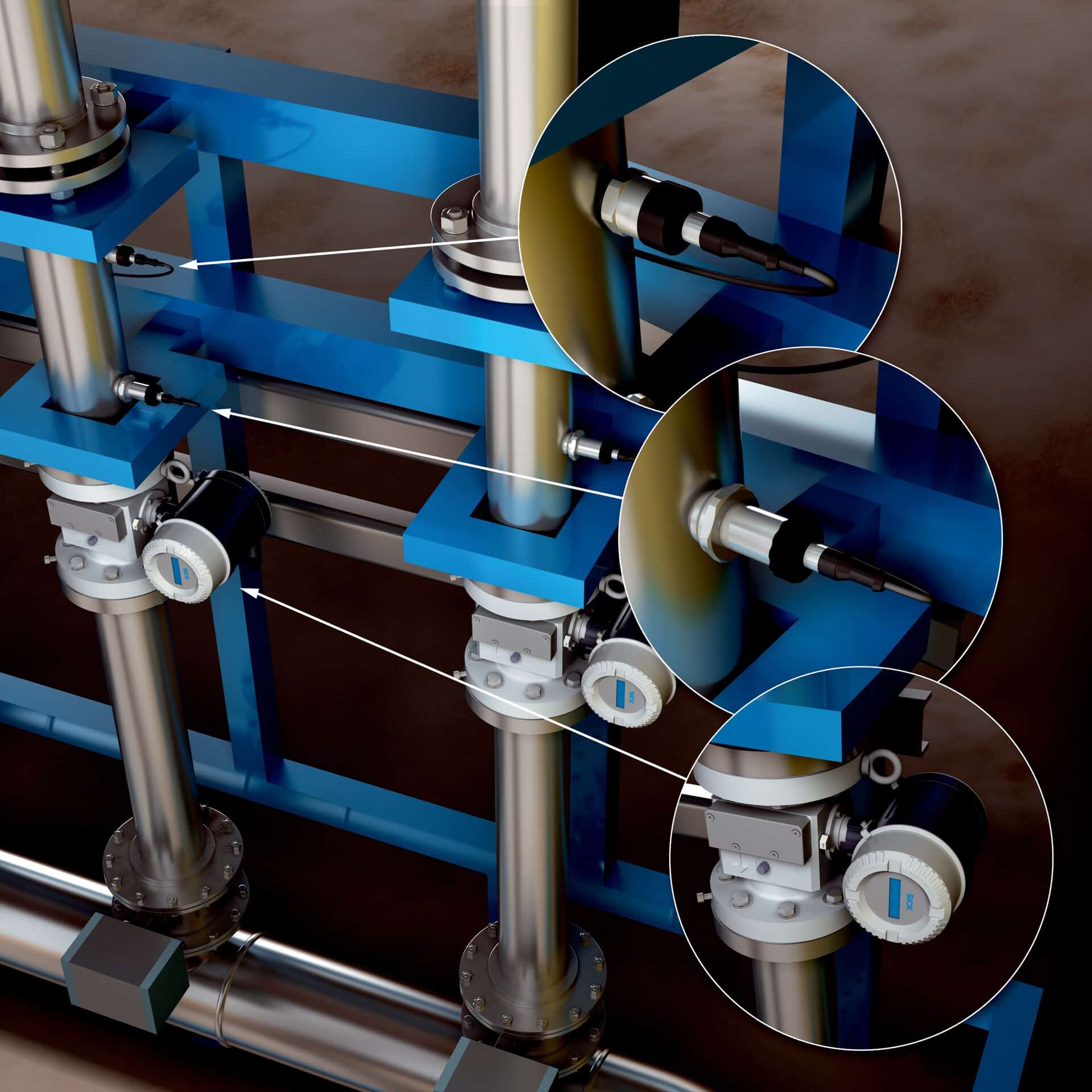

Flow Measurement Instruments

Monitoring gaseous emissions in plants requiring a permit is an important part of environmental protection. Pollutant emissions can be continuously measured, and limit values observed through the use of modern and reliable emission measuring technology. The measuring technology used must comply with the minimum requirements of international standards (e.g. EN 15267 and EPA Performance Specification 6) and prove its suitability by means of an EU type examination. FLOWSIC100 gas flow measuring instrument from Macrotec meets all these requirements: they combine the advantages of modern ultrasonic measurement with outstanding resistance properties and minimum maintenance.

Consistent measurement results even under extreme conditions

The measurement result remains unaffected by variations in gas composition, pressure, temperature, and humidity. The FLOWSIC100 continuously measures across the entire duct diameter, providing representative results. Its fully automated gain control function ensures signal transmission, while the integrated check cycle periodically validates the device’s functions. The FLOWSIC100’s self-diagnosis feature continuously monitors all critical function parameters, generating warning messages in case of any deviations that could impact the measurement result.

- Gas temperature: -40°C to +450°C

- Duct/Pipe diameter: 0.15m to 13m

- Cross-stack or one-sides options available

- High dust option available

- Compliant with regulations

- Compliant with international standards

SICK FLOWSIC100

All versions:

- Rugged titanium converters for long service life.

- Corrosion-resistant material for use with aggressive gases (optional).

- Probe version PR for cost-saving, single-sided installation in duct.

- Automated operational check with zero and reference point test.

- Measurement principle: Ultrasonic transit time difference measurement

- Measured values: volumetric flow a. c., volumetric flow s. c., gas velocity, sound velocity, gas temperature.

- Nominal pipe size minimum: ≥ 0.15 m

- Nominal pipe size maximum: ≤ 13 m

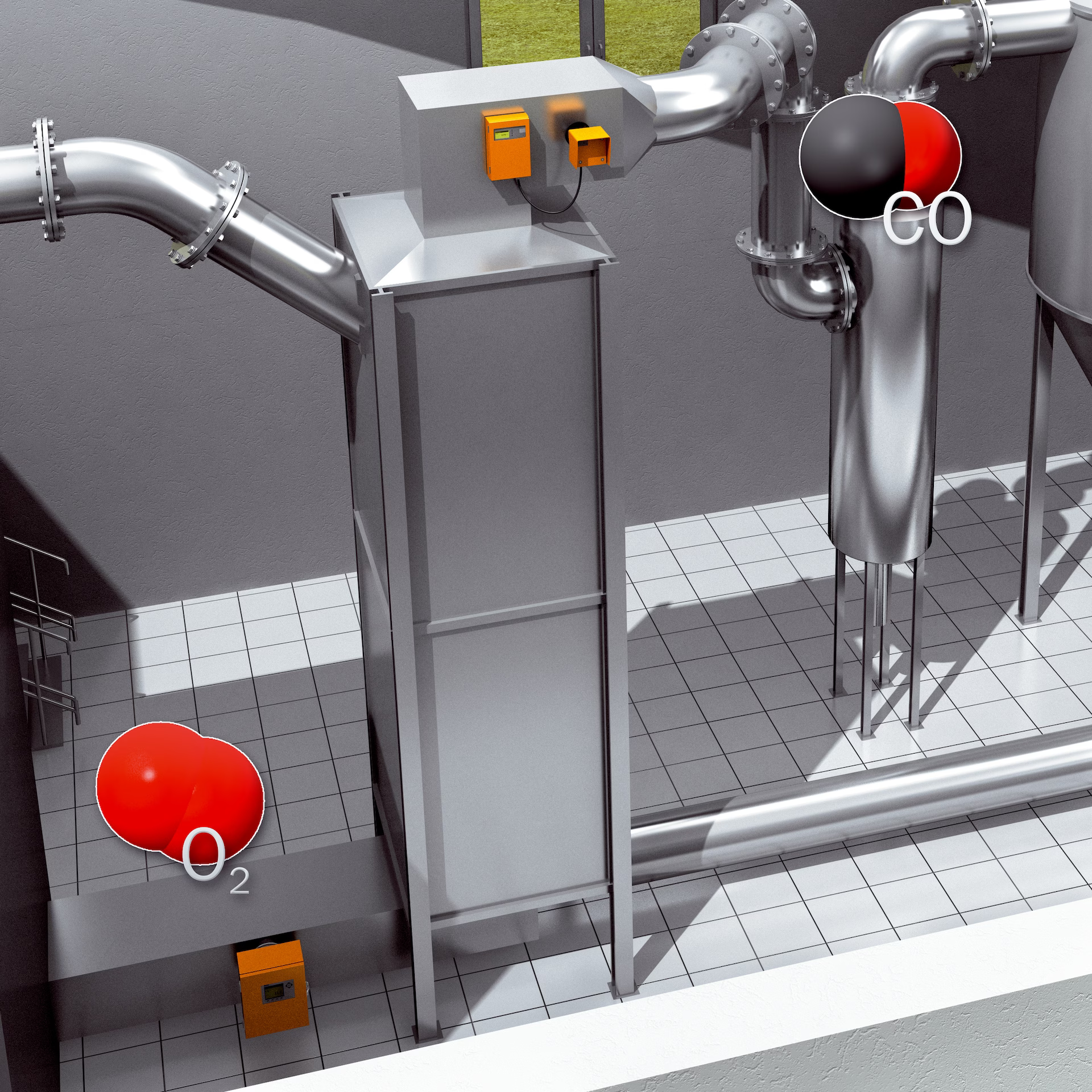

Oxygen Analysers

Reliable oxygen measurement is just as important for controlling an optimized combustion process as it is for emissions monitoring. In one of the toughest applications of industrial process automation, the analyser must be easy to integrate and extremely resistant.

Optimal combustion relies on the precise control of oxygen. Incomplete combustion, resulting from insufficient oxygen, leads to increased Carbon Monoxide (CO) emissions. Conversely, an excess of oxygen results in increased fuel usage. Macrotec’s oxygen analysers provides reliable measurements of oxygen levels immediately after combustion, allowing for real-time monitoring of the combustion process. This enables the setting of the optimal oxygen value for your fuel, ensuring efficient and effective combustion.

An extremely rugged solution unites very high quality and innovative performance. This makes it the first choice for incineration optimization – even in explosion-hazardous areas. And the ZIRKOR200 has another trick up its sleeve for safety-relevant measurements: It can be qualified in accordance with SIL 2 with 1oo1 (One out of One) as an option.

- ZIRKOR100 – for small systems, with temperatures up to 1,400⁰C.

- ZIRKOR200 – certified in accordance with EN 15267, it operates smoothly at process temperatures up to 1,600°C. The Ex types of the ZIRKOR200 are approved for IECEx and ATEX and are perfectly suited for applications in explosion-hazardous areas in Zone 1 and Zone 21. And qualified for SIL 2 with 1oo1 (One out of One), the ZIRKOR200 offers a high level of safety.

- ZIRKOR302 – the main difference between the ZIRKOR302 and the other two ZIRKON analysers is its automated calibration using the ambient air. The tried-and-tested flow sensor principle does not require any test gases for this calibration and ensures exceptionally precise, continuous measurement at temperatures up to 1,400⁰C.

A cost-effective solution for measuring in oxygen combustion systems, with two versions. Both versions utilise a fast response sensor with measurement below 4 seconds. Probe lengths of 200mm, 400mm, and 600mm.

- OXY-L – Designed to measure the oxygen concentration in air or gas mixtures with temperatures of -100 to 400⁰C. Applications include boilers burning oil, gas, coal, or biomass; incubators; composting probes.

- OXY-H – Designed to measure the oxygen concentration in flue gas mixtures with temperatures up to 950⁰C, with auto calibration using ambient air. Applications include furnaces, incinerators, cremators, or applications with high dust loads.

Related Articles

Guide to Choosing a Continuous Emission Monitoring System (CEMS)

Guide to Choosing a Continuous Emission Monitoring System (CEMS) Processes involving industrial-scale combustion are consistently subject to some type of air-quality environmental regulation. These regulations vary based on the specific […]