Dust Measuring Devices

Macrotec provides an array of Dust Measuring Devices. Our comprehensive services include the engineering and design of process monitoring requirements, equipment selection, installation, training, commissioning, maintenance, and remote monitoring. These systems are crucial for industries committed to adhering to environmental regulations and optimizing their operational efficiency.

The effective preservation of the environment hinges on the ability to detect and precisely quantify dust and particle emissions. This importance stems from the considerable impact that dust particles, particularly those originating from industrial sources, have on both human health and natural ecosystems. Additionally, the monitoring of airborne particles within indoor environments is gaining heightened relevance. SICK’s extensive range of products caters to both small and large measurement ranges and varying sizes of gas ducts, providing apt solutions for challenging measurement tasks like dust analysis in moist gases. Devices that have undergone suitability testing and feature automated zero and reference point checks are also part of the offering. Some models include advanced options like contamination monitoring or automatic self-adjustment, further enhancing the robust capabilities of SICK’s dust measurement devices.

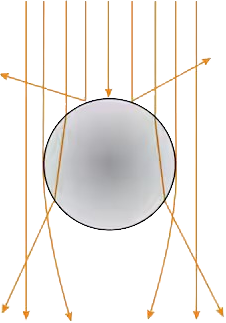

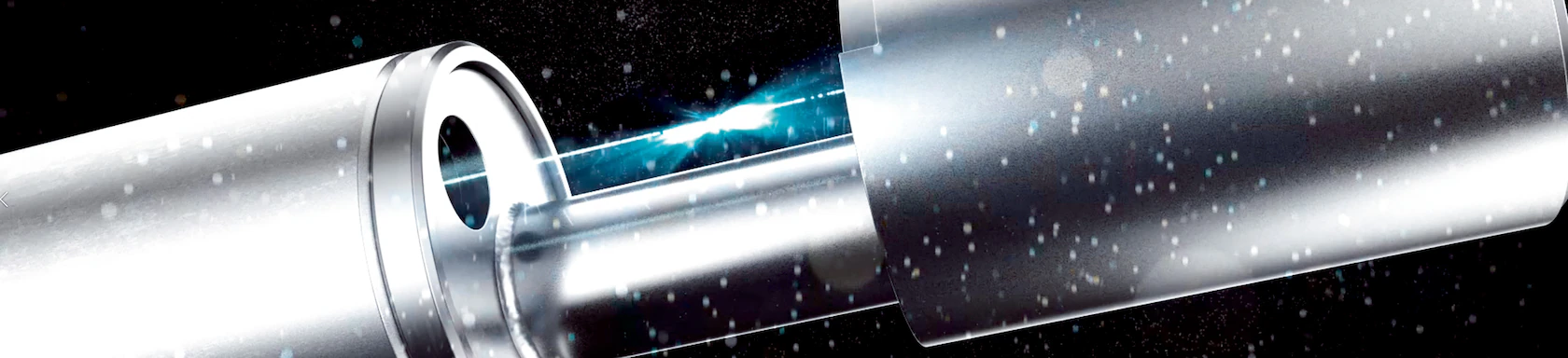

The choice between scattered light and transmittance measurement methods for detecting dust concentrations depends on specific environmental conditions. In transmittance measurement, the principle involves gauging the reduction in a light beam’s intensity, which occurs due to the absorption of light by particles. On the other hand, scattered light measurement offers two approaches: backward scattering and forward scattering. Backward scattering measures, the light reflected off the particles, while forward scattering relies on measuring the light that is scattered, refracted, or diffracted in the direction the light is initially projected. SICK incorporates all these measurement techniques in its range of dust measuring devices, ensuring an optimal fit for the diverse requirements of various measurement tasks.

Scattered Light Measurement

In the scattered light measurement technique, particles within a gas mixture scatter radiated light, which is then captured by a sensitive detector. This method is particularly effective for measuring low dust concentrations, even those below 1 mg/m³. Depending on the specific requirements of the system and the characteristics of the particles, either forward or backward scattering can be employed. Both approaches yield stable and repeatable results, unaffected by variations in gas velocity, humidity, or the electrical charge of dust particles. SICK, as a experienced manufacturer, offers dust measuring devices that utilize both forward and backward scattering techniques.

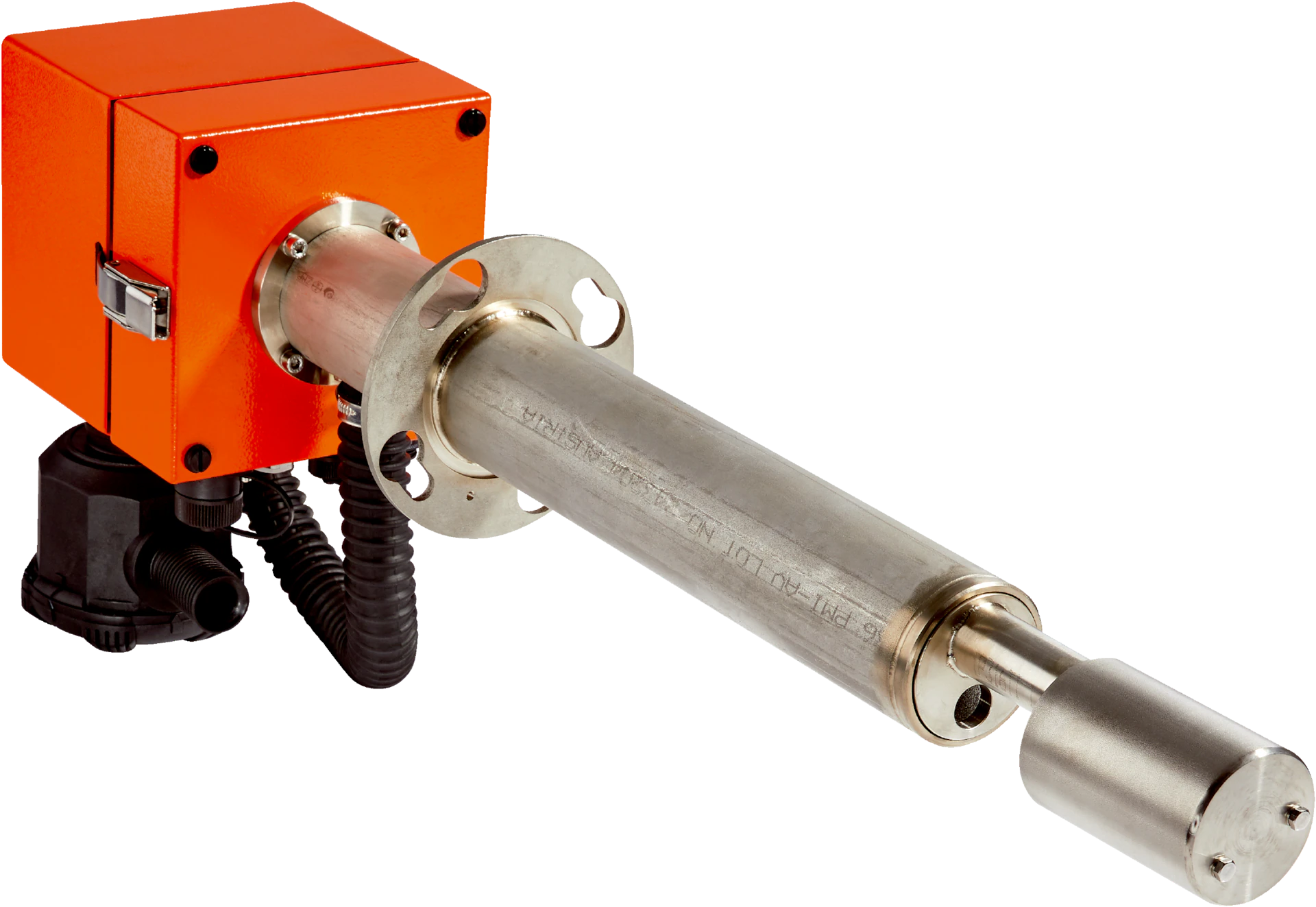

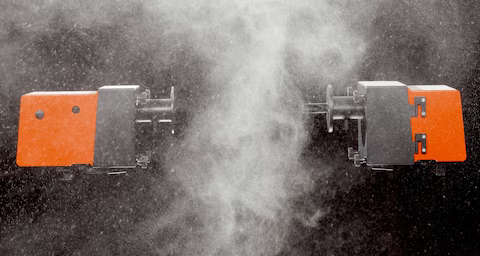

1. Backward scattering

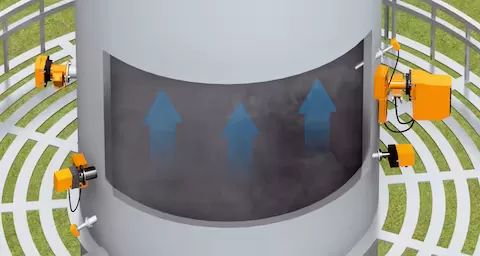

Light is irradiated into the measurement duct and the radiation reflected by particles is measured. It is suitable for larger gas ducts and delivers representative measurement results, even with inhomogeneous dust distributions.

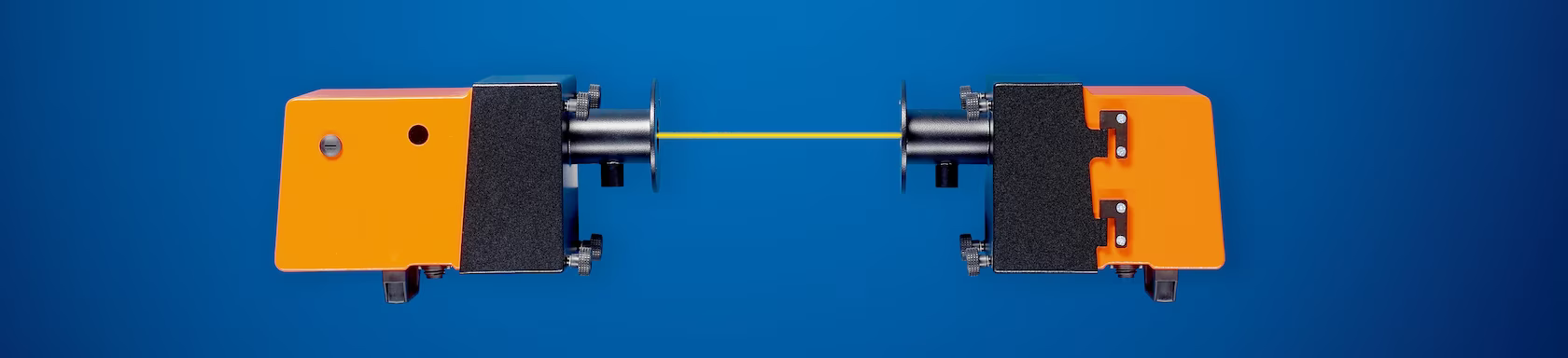

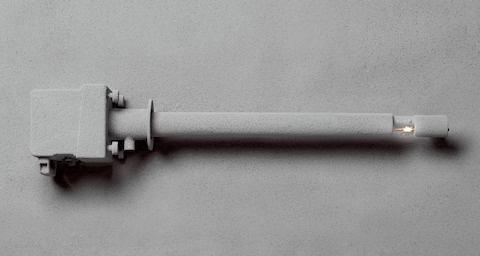

2. Forward scattering

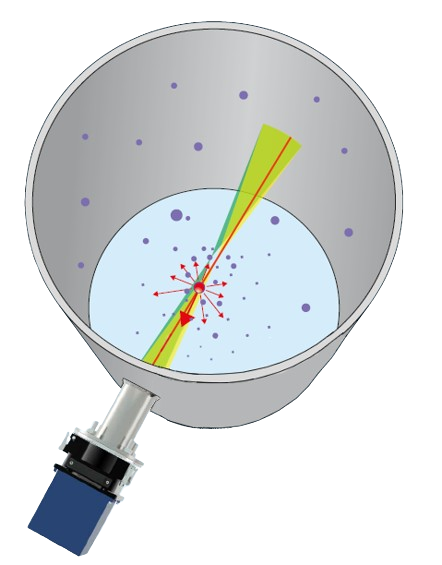

The dust measuring device measures the light scattering from the particles in the direction of diffusion of the measuring light beam. The measurement takes place in the gap of a measuring probe in the gas duct. Due to the smaller measuring volume, this measurement principle is also suitable for gas duct diameters below 0.5 m.

Light Scattering on Particles

A light source in the measurement duct emits light, which is scattered by particles in the gas mixture and detected by a sensitive receiver. The intersection of the transmitted beam and the receiver’s field of view constitutes the measurement volume within the gas duct. The intensity of the scattered light, which is directly proportional to the dust concentration, remains consistent regardless of the measurement distance. However, this intensity is influenced not only by the quantity and size of the particles but also by their optical properties. Accurate dust concentration measurement thus requires system calibration.

Advantages of Forward and Backward Scattering

The backward scattering method involves projecting light into the duct and measuring the light reflected by particles. This method is well-suited for larger ducts and provides reliable measurements even with uneven dust distributions. It also features background suppression to eliminate interference from other light sources.

Forward scattering, on the other hand, measures light scattered in the direction of the light beam’s diffusion. This measurement occurs in a probe gap within the gas duct. Due to its smaller measurement volume, it is also appropriate for gas ducts with diameters less than 0.5 meters.

Both methods are effective for low to very low dust concentrations and have the added benefit of requiring installation on only one side of the gas duct.

Measuring in Wet Gases

For precise dust measurement in moist gases, it’s necessary to dry the particles, as moisture can skew the results. The device extracts a sample of the gas using a probe, while ensuring that the measurement is unaffected by the gas flow rate in the duct. A thermal cyclone dries the particles, followed by the measurement of dust concentration. Forward scattering is preferred in this context due to its minimal measurement volume requirement. The sample gas is transported using an ejector system without moving parts, ensuring low maintenance. In scenarios like the fertilizer industry, where gas may contain salt solutions, optional backflushing is available to further reduce maintenance needs.

SICK™ DUSTHUNTER-SB30

SICK™ DUSTHUNTER T200

SICK™ FWE200DH

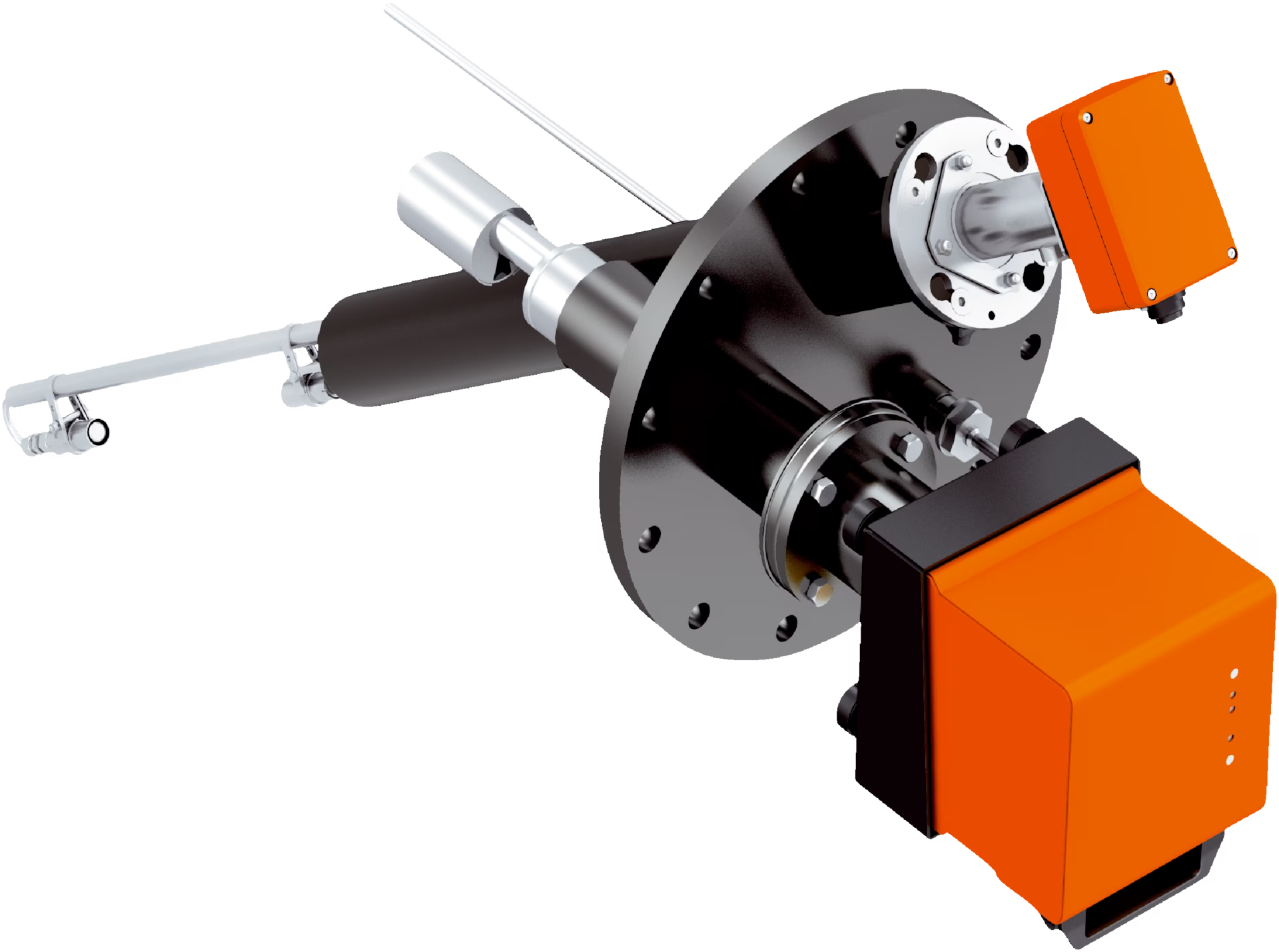

Transmittance Measurement

Transmittance measurement technology operates by detecting the reduction in light intensity caused by dust particles. Devices based on this technology are particularly effective for medium to high dust concentrations and are well-suited for use in large gas ducts. They find applications in emission and process monitoring, as well as in monitoring indoor air quality. These devices measure across the entire diameter of the gas duct, which helps to offset any uneven distribution of particles, resulting in highly representative measurement outcomes. An advantage of these devices is that they do not extend into the gas duct, avoiding direct contact with potentially aggressive process gases.

They also feature an optional function for contamination correction, which adjusts for gradual soiling of the optical surfaces. The measurement results can be displayed in various forms, including dust concentration, transmittance, absorbance, and opacity.

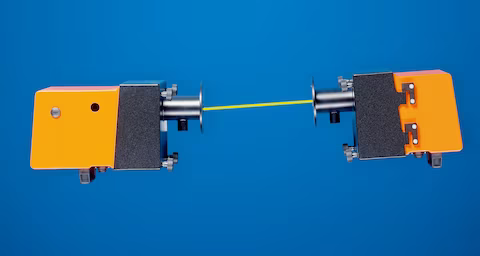

Principle of Transmittance Measurement

In transmittance measurement, a light beam is passed through a gas-particle mixture, with its intensity diminished by the particles present. The greater the number of particles in the light path, the more significant the attenuation of the light. The device calculates the transmission and absorbance by comparing the intensity of the received light, which has been attenuated, with that of the original, unattenuated light. Absorbance is directly proportional to dust concentration. In SICK’s transmittance measuring devices, the light from the source is reflected back to a highly sensitive receiver by a reflector positioned opposite it, effectively doubling the measuring distance and enhancing the sensitivity of the device.

Impact of Particle Properties

While particle properties have a lesser impact on transmittance measurement compared to scattered light measurement, particle size still plays a crucial role. Accurate measurement thus necessitates calibration. SICK’s cross-duct solution in transmittance measurement addresses issues arising from uneven particle distribution in the gas duct, as the measurement beam spans the entire duct. SICK’s extensive experience and application knowledge are integral to the design of its measuring devices.

Accommodating Various Gas Duct Diameters

SICK offers measurement solutions for a wide range of gas duct diameters, from small 0.5m ducts to large 50m ducts. Particularly in larger ducts, factors like lateral wind pressure or temperature variations can cause duct deformation. To counter any misalignment of the optical axis that may result, an optional “Automated self-alignment” function is available. This feature continuously monitors and corrects the orientation of the optical components, ensuring accurate beam alignment. Additionally, SICK provides suitable flange plates as accessories to fit various gas duct materials and wall thicknesses.

SICK™ DUSTHUNTER-SP100

SICK™ DUSTHUNTER T200

SICK™ Combiprobe CP100

Dust Measuring Devices from Macrotec & SICK

To effectively carry out a measurement task, it’s essential to consider a variety of factors and requirements beyond just choosing the right measurement technology. The more accurately and comprehensively these requirements are understood and defined, the more reliable and cost-effective the implementation of the measurement task will be. This is true not only during the procurement phase but throughout the entire lifespan of the measurement technology.

SICK stands out in this regard with its wide range of products and proven measuring technologies, supported by decades of experience and thousands of installations.

Gas Duct Diameter

The diameter of the gas duct where measurements are taken is a critical factor in selecting appropriate measuring devices. For large to very large gas ducts, devices that can measure in a larger space, such as those from the DUSTHUNTER SB series or, for very high dust concentrations, the cross-duct versions of the DUSTHUNTER T series, are needed to ensure representative measurements. For smaller gas ducts, devices with a limited measuring volume like the DUSTHUNTER SP are suitable.

Process Temperature

At higher temperatures, devices that do not protrude into the gas duct, such as the DUSTHUNTER SB versions with backward scattering or the DUSTHUNTER T transmittance measuring devices, are required. The DUSTHUNTER SP types are more appropriate for lower temperatures. In conditions where the dew point is low, leading to humid environments in the gas duct, the FWE200DH extractive dust measuring device is the ideal choice.

Measuring Medium

For aggressive measuring media, the non-contact scattered light devices of the DUSTHUNTER SB series or the cross-duct devices of the DUSTHUNTER T series are particularly suitable. The DUSTHUNTER T devices are effective for inhomogeneous media, as they measure in a relatively large volume, providing representative results. The FWE200DH is the best option for humid gases, while the DUSTHUNTER SP100 or SP30 are used for less challenging media.

Dust Concentration

For low dust concentrations up to about 200 mg/m³, the scattered light devices from the DUSTHUNTER SB and SP series are ideal. For higher concentrations up to about 10,000 mg/m³, the DUSTHUNTER T transmittance devices are more suitable. The DUSTHUNTER C200, which combines transmittance and scattered light measurement, is used when dust concentrations vary widely, such as with changing fuels.

Test Functions

All SICK dust measuring devices come standard with an automated zero and reference point check, as required by standards like EN 14181. Mid-range and higher-priced devices include an integrated contamination monitoring system for the optical surfaces. The DUSTHUNTER SB50 and SB100 models also feature automated background suppression, while the DUSTHUNTER T100 and T200 boast integrated self-alignment of optical elements.

Approvals

Dust emissions are regulated in many countries, necessitating approved measurement technology for monitoring.

SICK provides devices that meet current standards and regulations, such as EN 15267, EN 15859, MCERTS, as well as standards from the American EPA and Russian GOST.

Suitability-tested Ex types are available for potentially explosive environments, in accordance with 2014/34/EU (ATEX).

Particle Properties

Dust varies greatly in terms of size, shape, colour, material, density, and specific properties like abrasiveness or stickiness. It can range from relatively uniform particles like coal dust to highly heterogeneous mixtures like household dust, which includes a variety of substances.

Impact of Particle Properties on Measurement

For accurate dust and particle concentration measurement, many factors must be considered, including the selection of a suitable measuring point for representative results.

Gas velocities, flow conditions, particle properties, concentration, and humidity are all crucial in choosing the right measurement principle. Additionally, process and ambient conditions like corrosiveness, temperature, and particle types in the process are vital considerations requiring extensive experience in selecting the appropriate measurement technology.