Industry Solutions – Mining

We place a strong emphasis on developing and providing the products and services that clients require, providing the best technological solution, and providing quality products and services.

Certification

Macrotec is certified to the following standards:

ISO 9001:2015 | Quality Management Systems

ISO 14001:2015 | Environmental Management Systems

ISO 45001:2018 | Occupational Health & Safety Management

Our Featured Clients

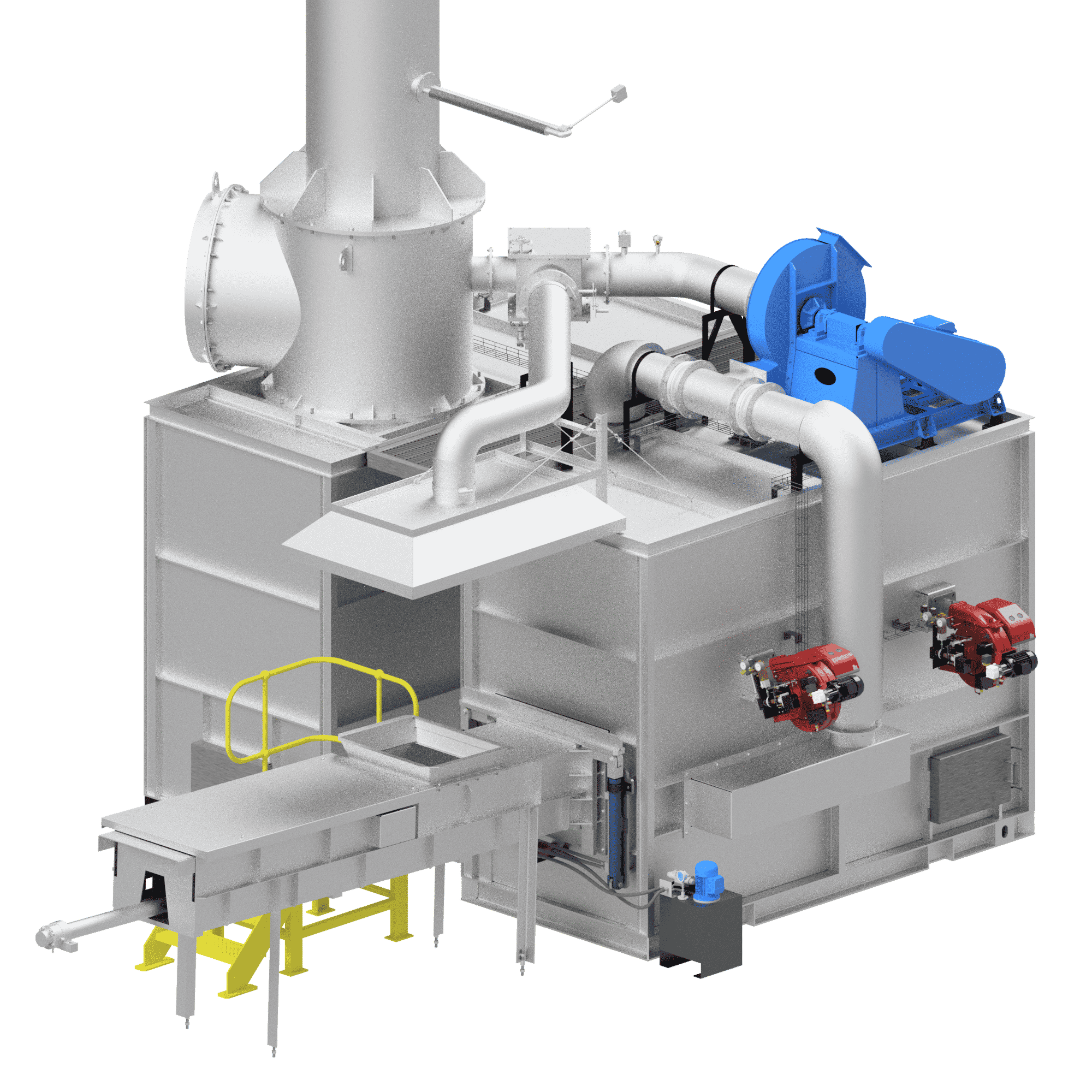

Incinerators

We design and manufacture a wide range of incinerators for various applications and conditions. Hazardous and other speciality waste types have always been a key focus area for us, along with the design of custom solutions.

Our incinerators have been designed to reduce every possible threat to the environment, while providing a reliable and cost-effective solution. We make use of advanced designs in our combustion plant, which regulates the combustion rate, temperature in the different chambers, turbulence, gas velocities and supply of oxygen.

All our incinerators are optimized to minimise emissions, with large combustion and settling chambers, high velocity combustion air, and high output burners. We also offer Incinerators with Filtration for units that must comply to EU emission regulations.

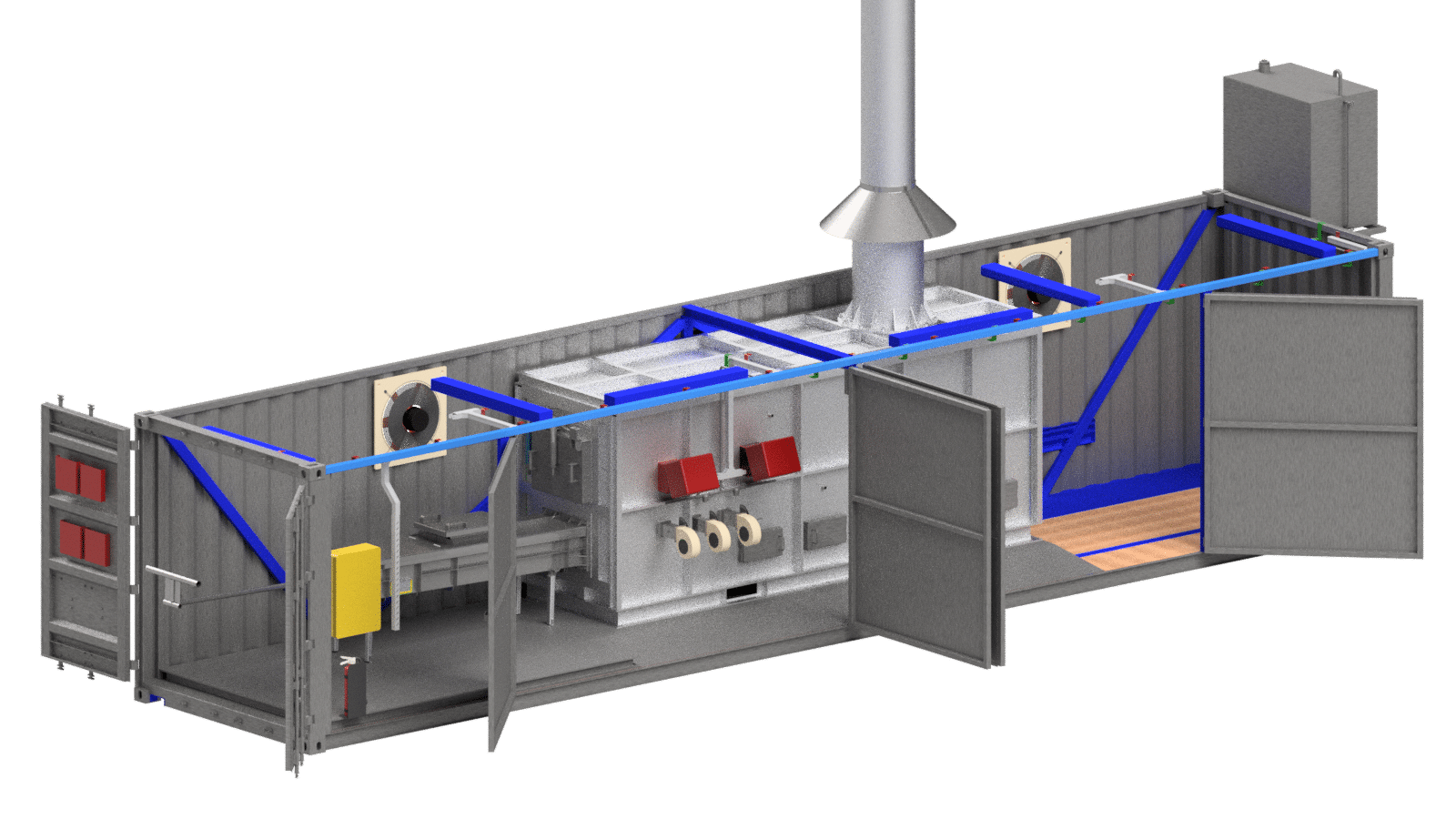

Our Incinerators are two chamber units, with auxiliary burners, combustion air fans, manual or auto feeder, and a stack. Optional items include: Manual and Auto feeders, Containerised Incinerators, Remote Monitoring and Support.

Our Incinerators are available in three different types:

Standalone Incinerators

These are our standard incinerators that are used all over the world. These incinerators offer reliability, easy maintenance, low emissions, various feeding systems, and can handle multiple waste types.

Biomass Incinerator

These Incinerators use biomass to heat up and maintain the required temperature, with no diesel or gas required as an auxiliary fuel. Also available in an option that does not require electricity.

Incinerators with Scrubbing and Filtration

Our solution for ultra-low emissions, these incinerators are integrated with dry gas scrubbing, flue gas filtration, and heat recovery. These plants comply with South African and EU emission regulations.

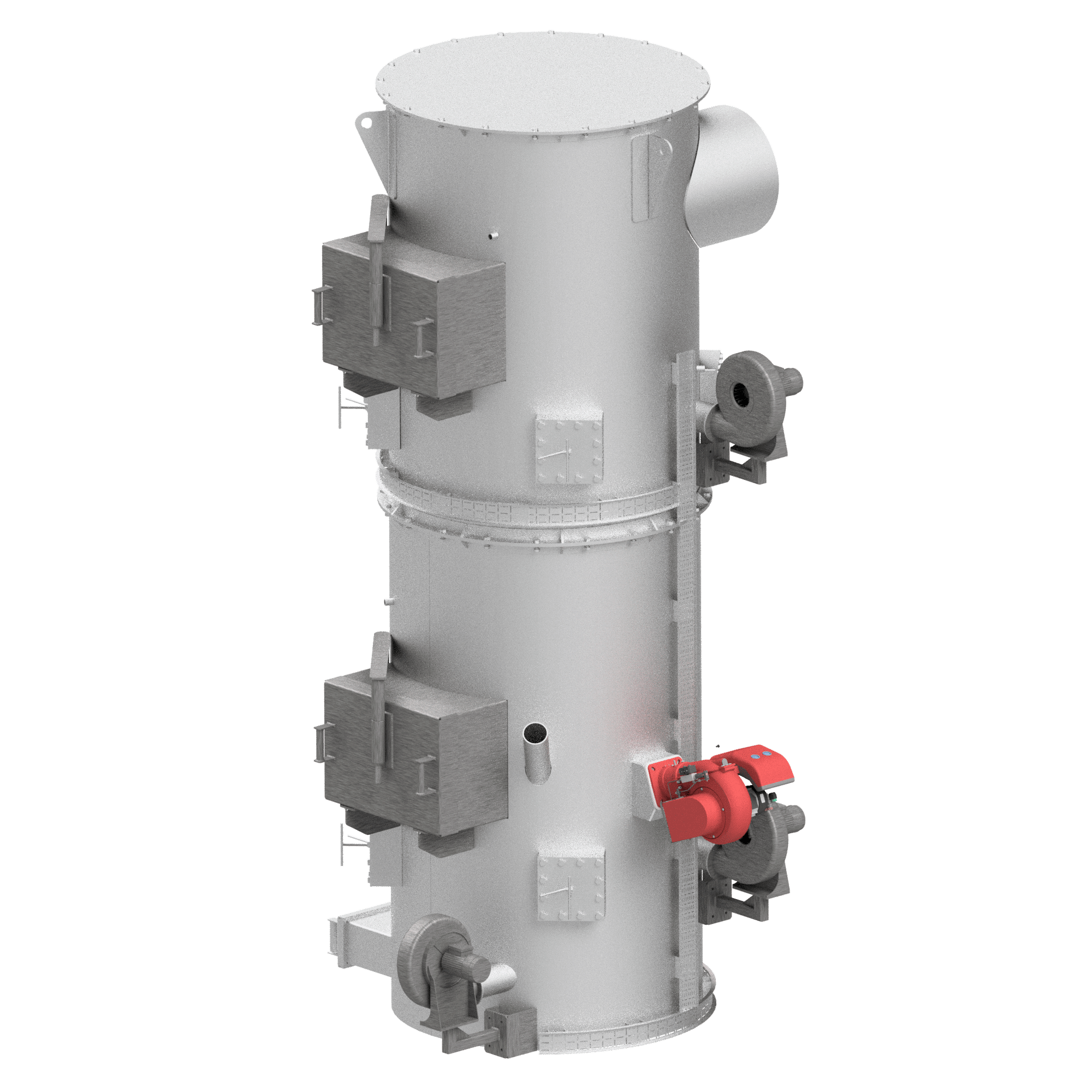

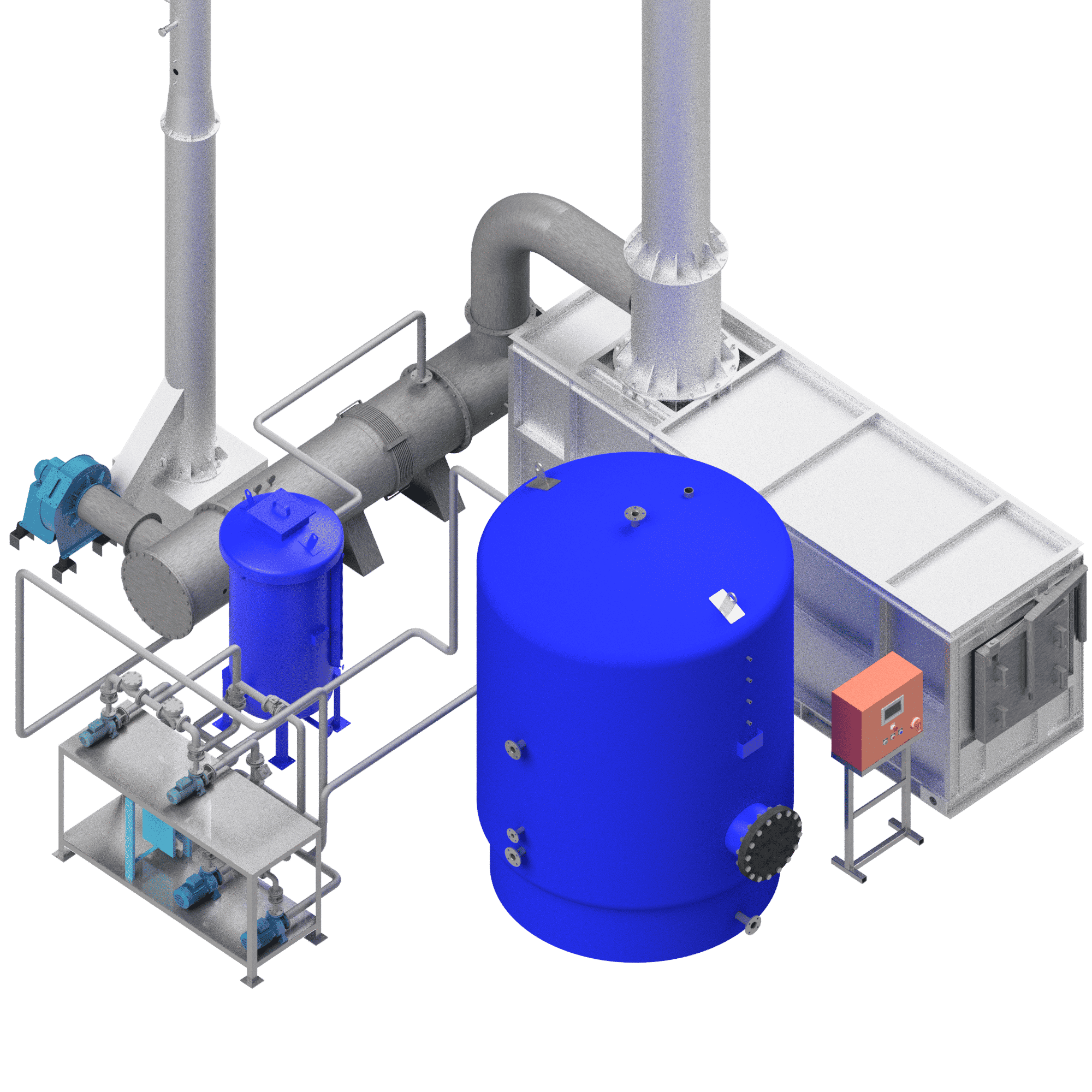

Carbon Fines Gold Recovery Incinerator

Our Carbon Fines Incinerator is the tried and tested method for recovering gold from carbon fines removed from the elution circuit. Our technology has been adopted by most of the major mining houses and gold recovery firms.

The carbon fines incinerator utilises a thermal process that burns off the carbon and other combustibles and captures the gold ash in a high efficiency filtration system.

The process has been optimised to ensure extremely low amounts of unburnt carbon, separation of most of the grit and silica from the ash, high fuel efficiency, and extremely high levels of recovery.

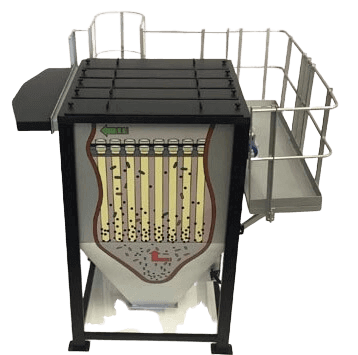

Hot Gas Filtration

Our filtration system is used on Incinerators, Furnaces, Mineral Processing Applications, Product Recovery, and other industrial applications for the removal of particulate matter (dust) to below to below 5 mg/m³. Dry Gas Scrubbing can be incorporated for the removal of acid gasses, dioxins, and heavy metals.

Our filtration systems utilise ceramic filter elements for high removal efficiencies, operating temperatures of 1,000⁰C for the filter elements, and 450⁰C for the filter bodies.

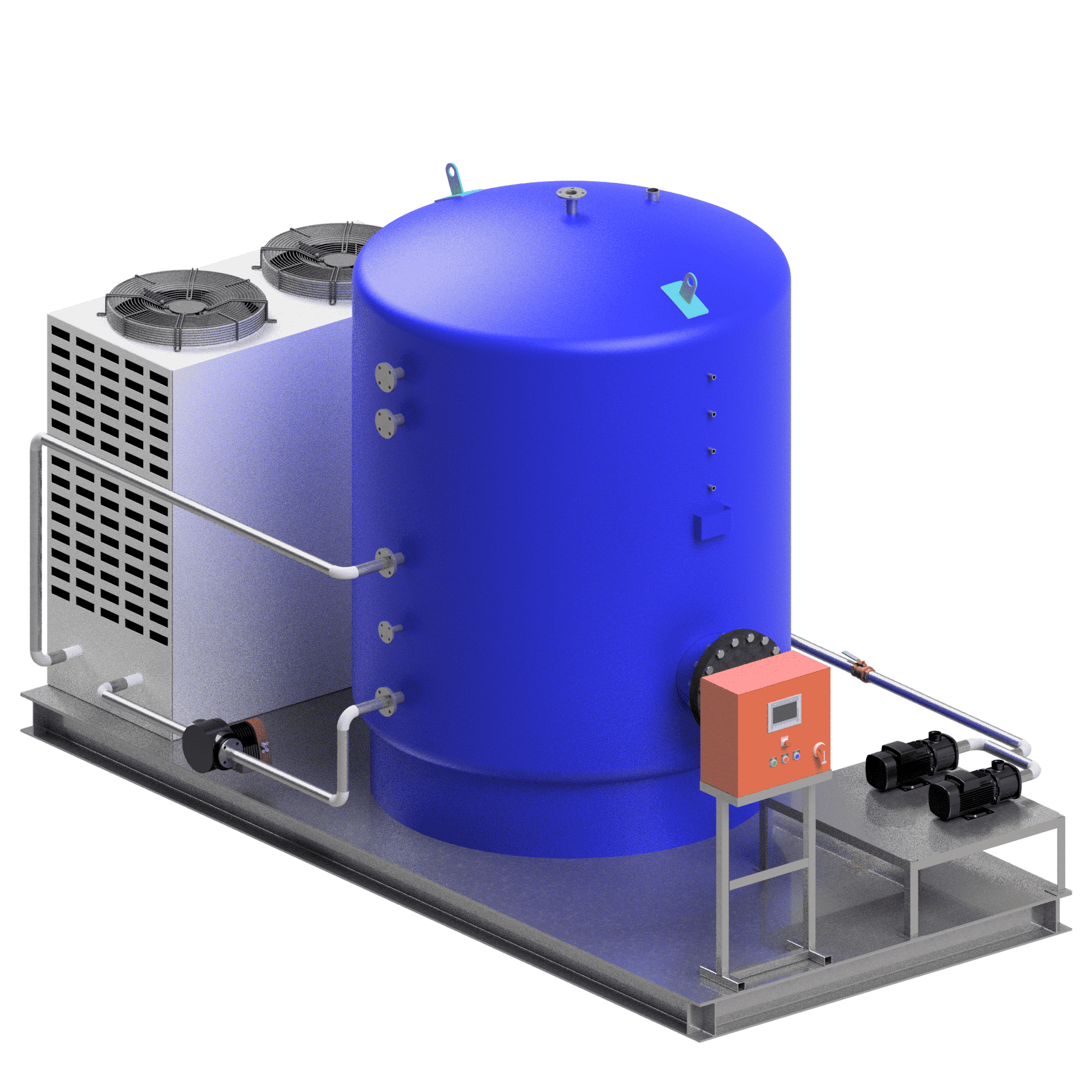

Hot Water Systems

Our heat recovery systems provide cost effective methods to provide heating in remote or off the grid locations.

Heating can be done via electrical elements, heat pumps, or waste heat from chillers, compressors, or an incinerator. Multiple heating sources can be used for redundancy.

Our hot water systems are completely pre-installed on a skid and includes the control system as per client requirements. A monitoring system can be optionally added

Heat Recovery

Our heat recovery systems provide cost effective methods to provide heating in remote or off the grid locations.

Waste heat recovery options include:

- Incinerators

- Chillers

- Compressors

To add redundancy to the system, a conventional heating source can also be added.

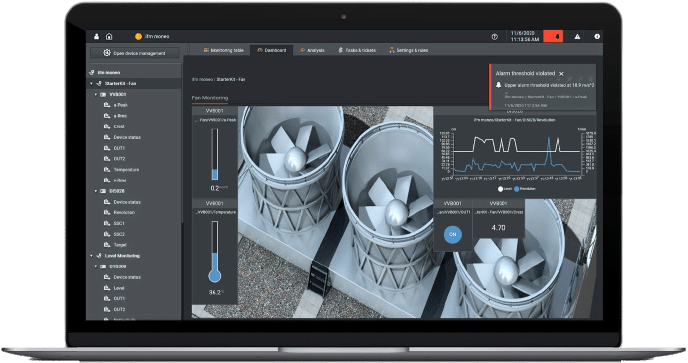

Equipment & Plantroom Monitoring

Our IIoT (industrial Internet of Things) platform allows you to easily monitor equipment and sensor data.

Our sensors allow Performance & Condition Monitoring of fans, motors, pumps, cooling and heating systems, and compressors. This allows you to optimise operation, reduce costs, and plan maintenance better to prevent unplanned downtime.

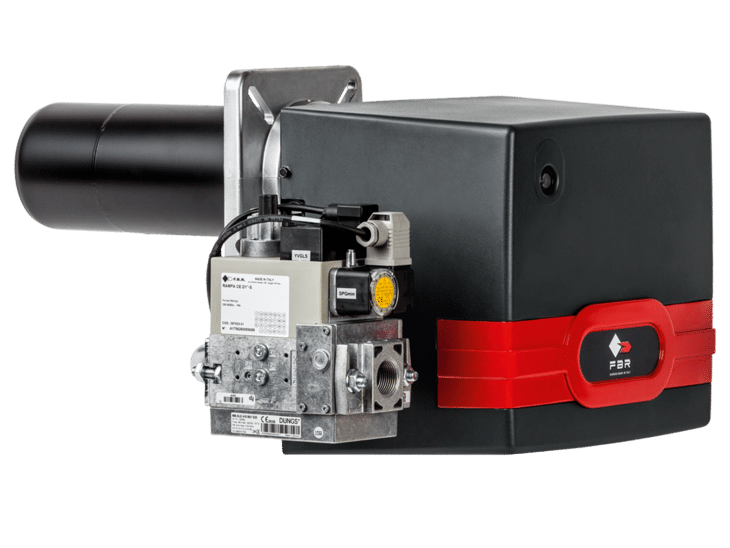

Burners

We supply, install, and maintain a wide range Diesel, HFO, LPG, Natural Gas Burners, Waste Oil, and Dual Fuel burners and burner spares, along with Burner Management Systems.

Instrumentation

We supply, install, and provide complete solution engineering for Process and Condition monitoring systems. This includes a wide range of Process Sensors, Position Sensors, Flue Gas Sensors, Condition Monitoring instrumentation, and Industrial Gateways.

Maintenance & Repairs

With our site services team we offer complete maintenance solutions, including mechanical, electrical, electromechanical, and refractory work.