Flue Gas Analyser Comparison

In-Situ vs Hot / Wet vs Cold / Dry

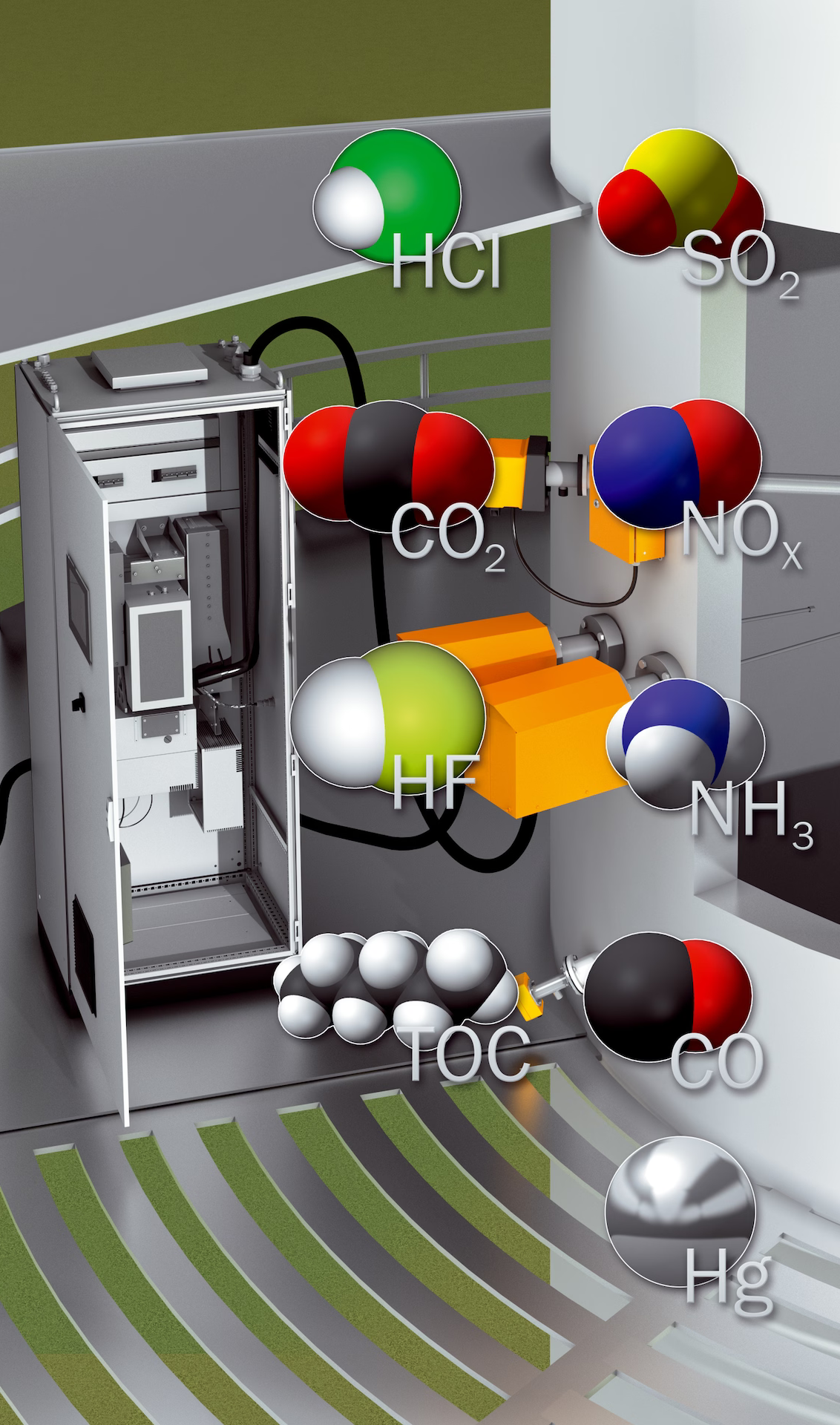

Flue gas analysis plays a pivotal role in optimizing combustion processes, reducing emissions, and adhering to environmental regulations. By measuring the concentration of various gases in flue emissions, industries can achieve efficient fuel usage, minimize pollutant release, and ensure compliance with environmental standards. This blog post delves into the different types of flue gas analysers, categorizing them into Extractive (subdivided into Hot and Wet, and Cold and Dry technologies) and In-Situ (including cross-duct and measuring probes versions). We will explore their functionalities, compare their methodologies, and discuss their applicability based on fuel types, regulatory compliance, stack gas conditions, and lifetime costs.

As flue gas exits the stack, it primarily consists of nitrogen, residual oxygen, various pollutants, and a significant amount of water vapor (5–40%). Given that the gas is typically hot, exceeding 95°C (>200°F), it has a higher capacity to hold water vapor compared to air at ambient temperature. Consequently, the dew point of the flue gas is usually lower than its exit temperature but higher than the ambient temperature. This leads to water condensation when the gas reaches the atmosphere.

If the flue gas sample sent to the analyser cools down, two key changes occur. Firstly, water vapor condenses. Secondly, certain pollutants, such as SO₂, dissolve in the condensed water. This dissolution reduces their concentration in the gas that reaches the analyser, leading to an underestimation of their actual levels. Additionally, the resulting condensate is acidic and can be corrosive, which may cause further complications.

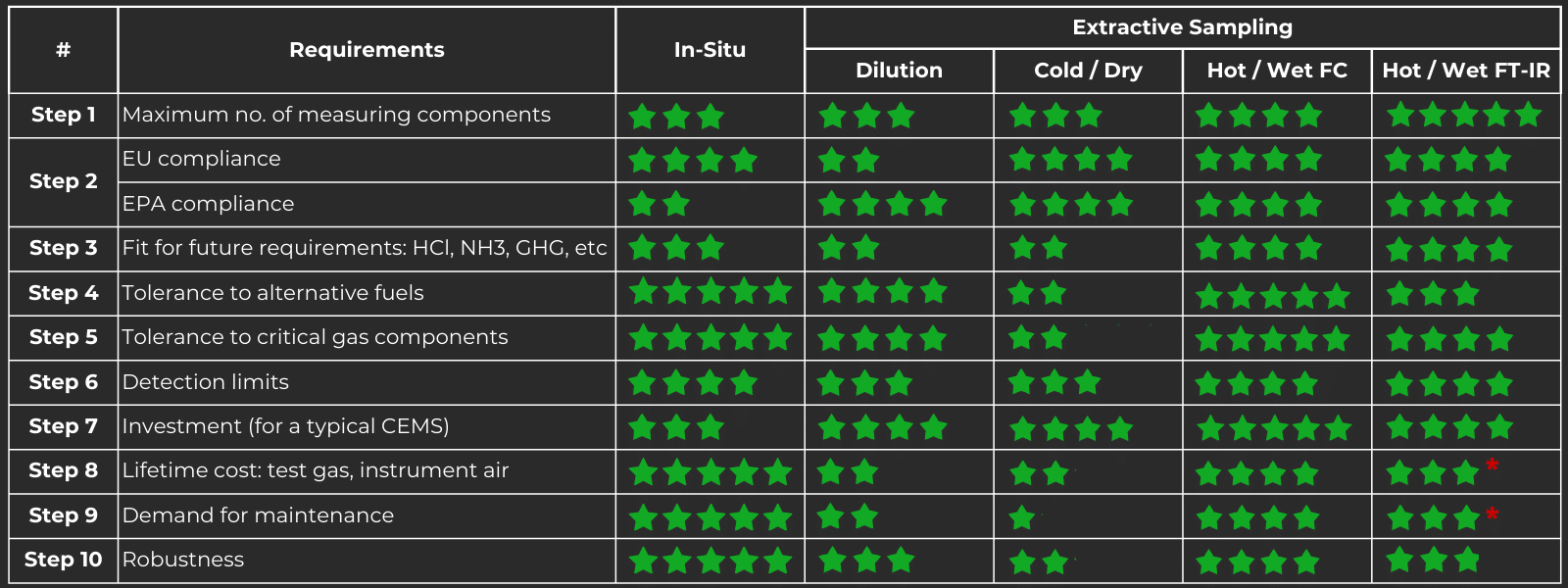

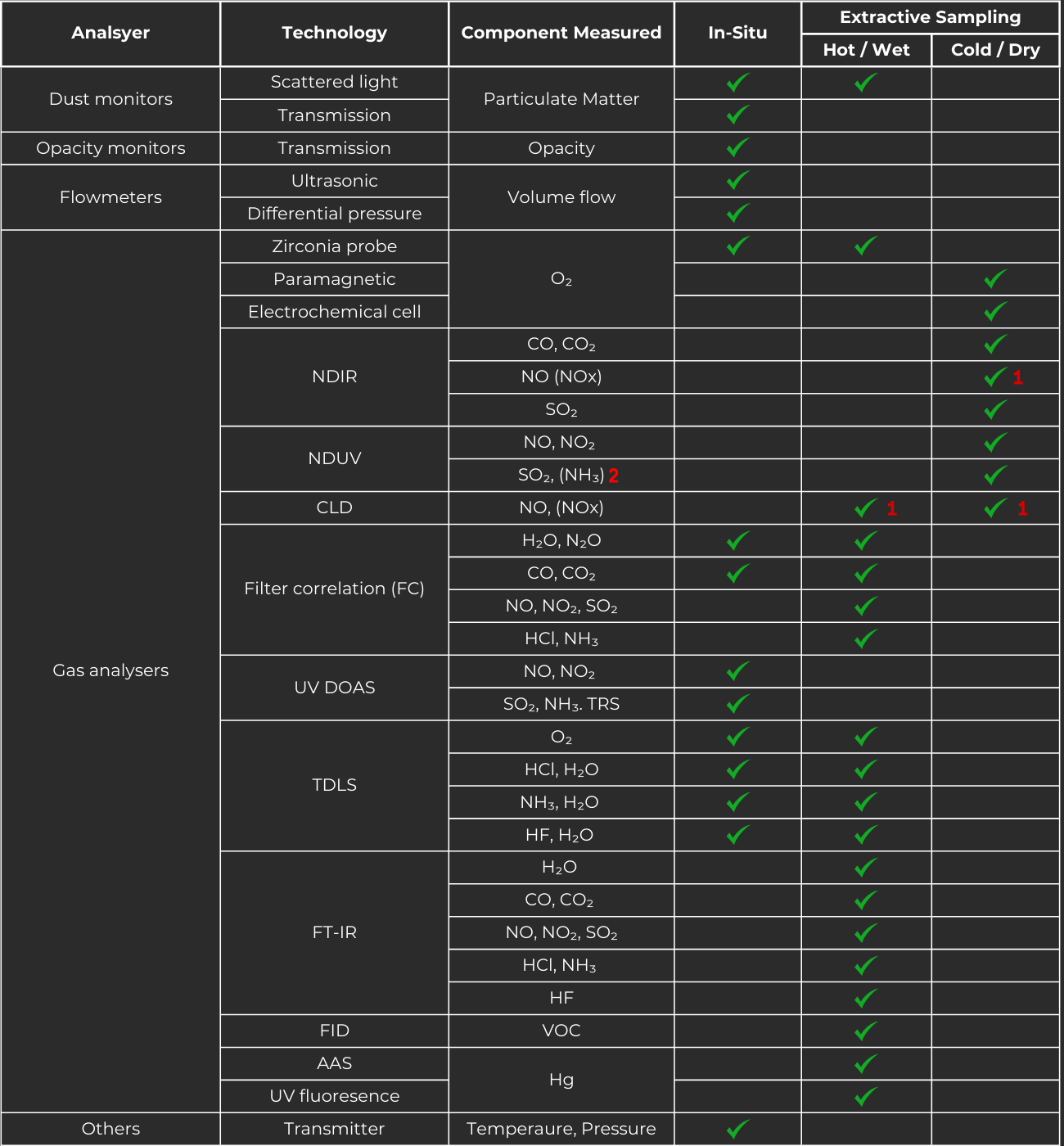

There are two primary categories of analyser techniques suited for this task, as illustrated in Figure 1 below:

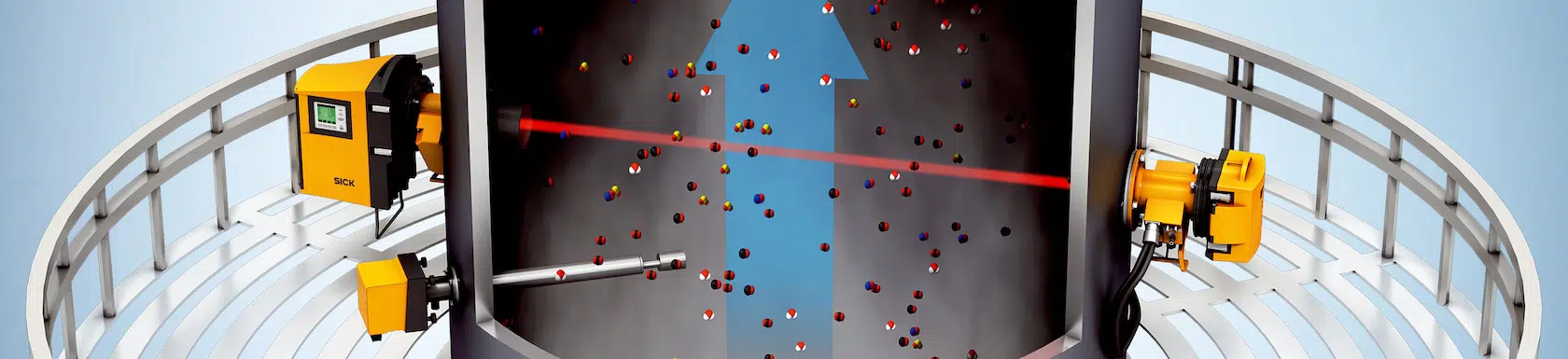

1. In-situ analysers, where the analyser is integrated directly into the stack.

2. Extractive analysers, where a sample of the gas is drawn from the stack and sent to the analyser for testing.

In-Situ Analysers

The In-Situ method has gained popularity due to its simplicity and low maintenance requirements. This method has removed the requirement for extraction and handling of the flue gas sample, greatly reducing complexity.

Where extractive systems require a gas sample to be extracted and sent to the analyser, in-situ analysers measure the components directly in the duct/stack through which the flue gas flows.

Advantages of In-Situ Analysers:

- Continuous and direct measurement, no sampling.

- Direct and unfalsified measurement.

- Fast measurement.

- Low maintenance.

- Cross-duct version for representative measurement results or

- measuring probe version for simple installation.

Disadvantages of In-Situ Analysers:

- Numerous analysers might be required depending on the process parameters that needs to be measured.

- Limitations on applications with high moisture and dust content.

Hot / Wet Analysers

The hot/wet CEMS approach has gained traction as analyser technologies have advanced, becoming more tolerant of higher operating temperatures. This development has reduced the necessity for chilled gas samples, paving the way for a simpler and more effective sampling technique.

In a hot/wet system, a single sample stream flows directly from the tap point to the analyser, bypassing any chilling process. The sample stream is kept as hot as necessary to ensure that all components remain above their dew points, thus preventing condensation. In environments with high concentrations of SO2, for instance, the temperature may need to be maintained between 160–190°C (320–375°F) to stay above the acid dew point.

In this system, all chemical components stay in their gas phase, mirroring their state in the flue-gas stream, both during and after analysis. The sample is then vented as a gas, meaning there is no liquid phase in the system. The data processing system associated with the analyser is responsible for converting the ‘wet’ readings to a ‘dry’ basis as needed. Mechanically, this approach is less complex than a cold/dry system and requires different analyser technologies for certain pollutants. This simplicity and the ability to analyse the components in their natural state make the hot/wet system an increasingly popular choice for certain applications.

Advantages of Hot/Wet Analysers:

- Mechanically less complex.

- Very robust

- Widest range of gas components can be measured.

- Able to measure under harsh process conditions.

- Lower maintenance.

Disadvantages of Hot/Wet Analysers:

- Higher capital costs

Cold / Dry Analysers

The cold/dry method is a prevalent extraction technique used across industries. This method has a long history of application, leading to its frequent specification or assumption in regulations.

In the cold/dry methodology the sample stream is passed through a thermoelectric chiller, cooling it to about 4°C (39°F). At this temperature, most of the moisture in the sample condenses and is removed. While this approach is mechanically complex, it is particularly effective for applications like boilers fired with pipeline natural gas, where the primary pollutant of concern is NOx. However, the cold/dry method can present challenges, especially when dealing with more complex fuel types and a broader range of pollutants to monitor.

One significant issue with this method is that some pollutants, especially particulates and certain acids, are water soluble. They tend to dissolve or get trapped in the condensate, effectively being removed from the sample. This leads to a substantial reduction in their concentration in the sample, rendering the readings for these analytes ineffective. Consequently, for situations requiring the monitoring of water soluble pollutants such as NH₃, HCl, and HF, the cold/dry approach is not suitable. Other analytes like NO₂ and SO₂ are somewhat water soluble, meaning water removal can impact their measurements. However, the error is usually minor, and regulatory bodies often accept compensated readings from the dried gas sample.

Advantages of Cold/Dry Analysers:

- Low CAPEX cost

Disadvantages of Hot/Wet Analysers:

- Higher OPEX and lifetime costs

- Smaller range of gas components that can be measured.

- Issues with water soluble components.