The Benefits of Pre-Heated Combustion Air

Pre-heated combustion air is a technique that involves heating the air used for combustion before it enters a furnace. This technique has gained attention as a means of improving the efficiency, performance, and environmental impact of combustion systems. In this article, we examine the advantages of using pre-heated combustion air in a furnace and explore the scientific evidence that supports these benefits.

Typical applications

- Industrial furnaces: For processes such as annealing, hardening, melting, and forging.

- Boilers: In power plants, commercial buildings, or residential heating systems to increase overall efficiency.

- Kilns: For ceramic, pottery, and brick production, to increase energy efficiency and lower fuel consumption.

- Incinerators: For waste disposal and energy recovery, to improve combustion and reduce emissions.

- Heat treatment ovens: For metal and non-metal materials, to increase the uniformity of heating and reduce energy consumption.

- Drying and curing ovens: For various industries such as food, paint, and textiles, to enhance efficiency and reduce energy usage.

- Baking ovens: In commercial and industrial food production, to improve energy efficiency and product quality.

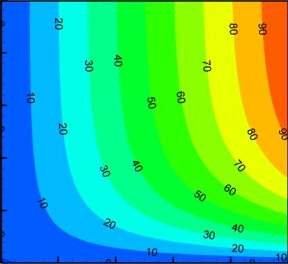

Energy Efficiency

The thermal efficiency of a furnace refers to the ratio of heat output to fuel input. Pre-heating combustion air can increase the thermal efficiency of a furnace by reducing the amount of fuel required to reach the desired temperature. This is because pre-heated air requires less energy to reach the ignition temperature than cold air. Several studies have demonstrated that pre-heating combustion air can increase thermal efficiency by up to 10%. This reduction in fuel consumption leads to cost savings and lower greenhouse gas emissions.

Combustion Quality

The quality of combustion refers to the degree of completeness and efficiency with which fuel is burned. Pre-heated combustion air can improve combustion quality by ensuring that the fuel and air mixture is at the right temperature and concentration for efficient combustion. This is because combustion depends on the ratio of fuel, oxygen, and heat, and pre-heating the combustion air can optimize this ratio. Improved combustion quality can lead to lower emissions of pollutants such as carbon monoxide and nitrogen oxides, as well as reduced formation of ash and soot.

Equipment Longevity

Pre-heating combustion air can also prolong the lifespan of furnace equipment by reducing thermal stress, corrosion, and erosion on furnace components. When the combustion air is not pre-heated, it can cause thermal stress on the furnace tubes and other components, leading to more frequent maintenance and repair costs. Pre-heating the air reduces the thermal stress on the furnace tubes and other components and reduces the accumulation of ash and other deposits that can cause erosion.

Safety and Environment

Incomplete combustion can lead to the formation of hazardous gases, such as carbon monoxide, nitrogen oxides, and volatile organic compounds. Pre-heated combustion air can improve the safety and environmental performance of a furnace by reducing the risk of incomplete combustion. This is because pre-heated combustion air ensures that the combustion process is more complete and efficient. In addition, pre-heated combustion air can reduce the risk of fires and explosions in the furnace.