Additional Services

We provide various Engineering, Maintenance, and Site Services, which include full process, chemical, mechanical, and electromechanical design. Services also include draughting, site implementation, operation, and maintenance.

Industries we have worked in include waste management, industrial, bottling, agriculture, crematoriums, dairy, and mining.

-

- Burner Management

- Combustion optimization

- Combustion monitoring

- Condition monitoring

- Equipment:

- Operation

- Monitoring

- Maintenance

- Furnace design

- Heat exchanger:

- Design

- Selection & Supply

- Heat transfer engineering

- Heat recovery solutions

- Industrial IOT

- Plantroom & Factory design:

- Plantroom Layout

- Factory layout

- Boilers

- Steam lines

- Compressors

- Compressed air lines

- Generators

- Hot water supply

- Repairs and maintenance

- Stack design:

- Chimney

- Flue gas stack

- Steam line design

- Burner Management

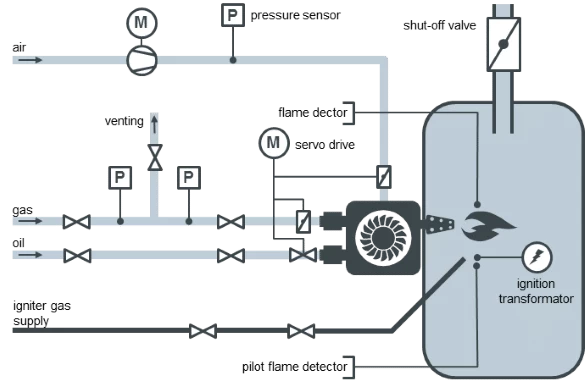

Burner Management Systems (BMS)

- Design of burner management systems, including:

-

- Mass balance of combustion reaction, fuel and combustion air requirements

- Design, supply, and installation of burner management systems, including oxygen analysers for improved combustion control

- Design, selection, supply, and installation of flue gas analysers to monitor combustion

- Selection and supply of packaged and furnace burners, combustion fans, and fuel trains

Combustion optimization

- Combustion analysis to identify areas of improvement

- Optimise combustion air and burner control for improved combustion and fuel consumption

Compliance monitoring

- Conduct compliance monitoring tests for combustion installations

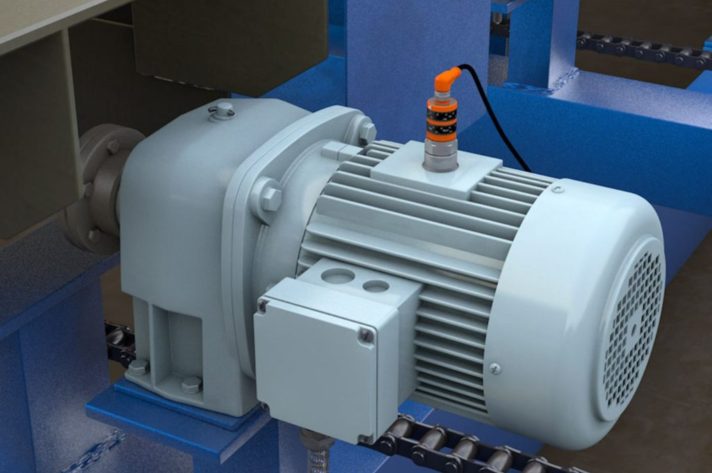

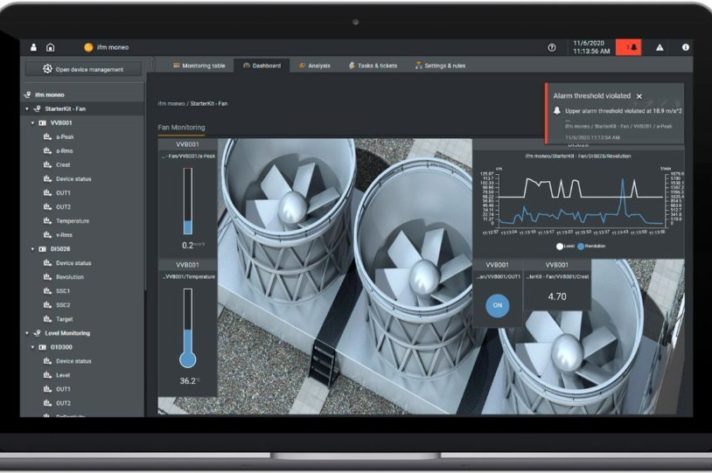

Condition monitoring

- Identify operational risks that require monitoring

- Supply and installation of instrumentation and monitoring equipment

- Design and setup of dashboard and monitoring software

Equipment operation, monitoring, and maintenance

- Complete equipment operation, including remote monitoring and assistance, with maintenance services to keep your equipment running

Furnace design

- Analyse customer requirements, waste specifications, regulations

- Custom furnace design to client requirements

Heat exchanger design and selection

- Heat exchanger design including:

-

- Analysis of fluid flow

- Heat transfer calculations

- Fouling factors

- Maintenance requirements

- Material selection

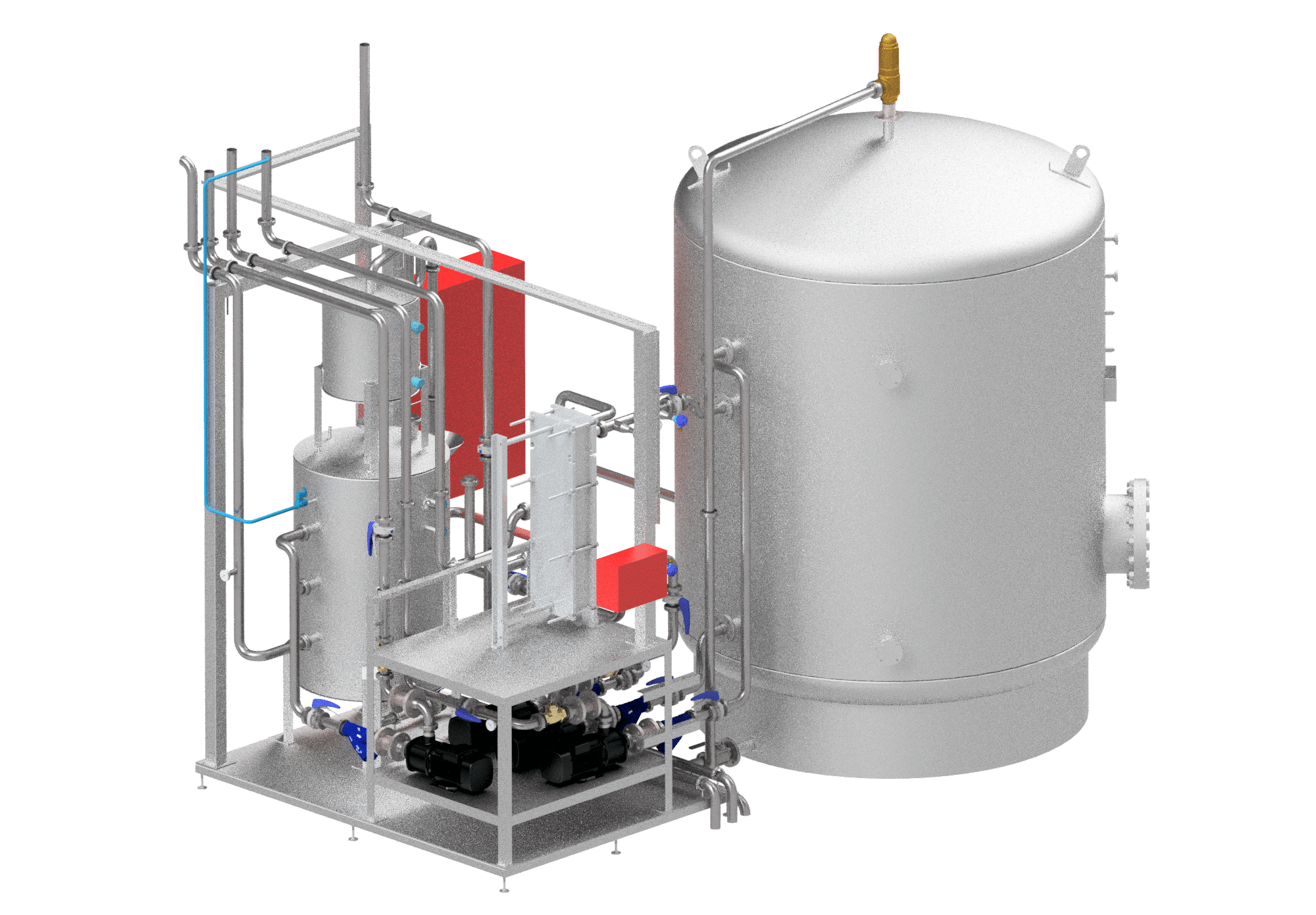

Heat recovery solutions

- Heat recovery solutions from various waste heat sources:

-

- Flue gas

- Industrial waste heat

- Compressors

- Generators

Industrial IOT (Internet of Things)

- Identify cost drivers and risk areas

- Supply and installation of sensors, instrumentation, and networking equipment

- Design and setup of dashboard and monitoring software

Plantroom & Factory Design

- Plantroom and factory layouts

- Utilities:

-

- Boilers and steam lines

- Compressors and compressed air lines

- Generators

- Hot water supply

Repairs and maintenance

- Repair and maintenance services for all products supplied by us, including:

- Furnaces – incinerators, cremators, biomass

- Tanks

- Ceramic filters

- Burners, including: packaged burners, furnace burners, burner management systems, burner control, fuel supply systems

Stack (chimney, flue gas stack) design

- Design of freestanding our guyeded stacks to the ASME STS standards

- Manufacture and installation of stacks

Steam line design

- Determine consumption rate of steam equipment

- Size pipework according to flowrate

- Determine amount of condensate formation

- Size steam traps according to condensate

- Size return lines according to steam consumption rate

- Determine if pumps are required for condensate return lines

- Determine if and what control valves are required

- Specify valves and steam line accessories

- Produce P&ID and CAD drawings